Revised A

31

6301

5. Maintenance

5.1. Shut down / Start up procedures

Important recommendations

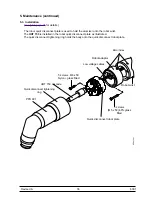

Follow the compressed air settings as described in section 3.2.

The rotor and the stator will be damaged if the bearing air is turned off.

Bearing air must be set at 90 PSI (6 bars) minimum at the quick disconnect plate.

(*For tubing lengths over 15’, measure air pressure at the quick disconnect to determine correct

setting.)

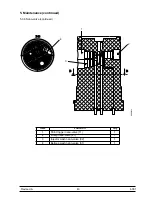

Make sure that there is a signal emitting from the speed board.

5.1.1. Shut-down procedures

Important steps to follow:

Step 1 - Stop atomizing

Step 2 - High voltage supply OFF

Step 3 - Circuit flushing cycle

Step 4 - Stop shaping air flow

Step 5 - Stop turbine drive and wait until Rpm = 0

Step 6 - Stop bearing air

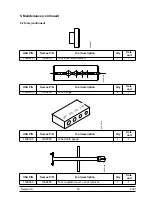

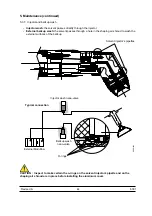

5.1.2. Start-up procedures

Important steps to follow:

DES01630

Bearing air on

Start turbine rotation

Shaping air on

High voltage on

Paint flow on

Timing

Step 1

Step 3

Step 4

Step 2