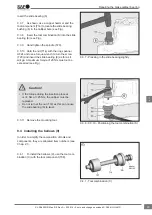

Insert the slide bearing (6)

9.3.7 As shown, use a copper hammer and the

tool component (T14) to locate the slide bearing

bushing (6) in the calliper bore (see Fig.).

9.3.8 Insert the tool combination (S) into the slide

bearing (6) (see Fig.).

9.3.9 Hand tighten the spindle (T20).

9.3.10 Hold the nut (T14) with the ring spanner

AF24 and use a torque wrench to turn the screw

(T20) and insert the slide bearing (6) as far as it

will go. A maximum torque of 25 Nm must not be

exceeded (see Fig.).

• If the torque during the insertion process

is <4 Nm or >25 Nm, the calliper must be

replaced.

• Do not turn at the nut (T14) as this can cause

the slide bearing (6) to twist.

Caution!

9.3.11 Remove the mounting tool.

9.4 Installing the bellows (9)

In order to simplify the composition of tools and

components, they are allocated item numbers (see

Chap. 2.1).

9.4.1 To install the bellows (9), use the tool com-

bination (C) with the tool component (T08).

9.3.7 - Pressing in the slide bearing slightly

9.3.8 - 9.3.10 - Positioning the tool combination (S)

9.4.1 - Tool combination (C)

Repairing the brake calliper bearing

43

en

XL-SA40001RM-en-DE Rev A • 02.2016 • Errors and changes excluded © SAF-HOLLAND