VISE JAW REPLACEMENT

Vise jaws (cartridges) are replaced in pairs as an assembly, a matched set consisting of (one top jaw

and one bottom jaw), you will need two sets for your key machine. You will disassemble and re-

install the old plungers, springs, and screws. Or you can buy a complete set with the plunger, top

jaw, bottom jaw, screws and springs. Simply drop the (cartridges) in place, you will need two

cartridges.

Coat all steel sliding surfaces with a light coating of grease when installing the vises.

8.

TOP SHOULDER KEY GAUGING

Standard cylinder keys should always be top shoulder gauged. Use the machines full-function flip-

up key gauges. We do not recommend bottom shoulder gauging because key blank manufacturers

do not always maintain a reliable correlation between bottom and top shoulder positions on the key

blanks they make.

Always remember to flip DOWN your key gauges before cutting a key. Failure to do will prevent your key

machine from cutting the key.

7

Fig. 4

RY10054 Key Gauge

Protector (red)

RY10049Key Gauge Shaft

RY9278 Vinyl Cap (red)

Key Gauge

RY10050 Left-Hand Key Gauge

RY10048 Right-Hand Key Gauge

Key Vise Knob

(

with)

RY82

3-piece Thrust

Bearing Assy.

Top 4-way Jaw

Bottom 4-way Jaw

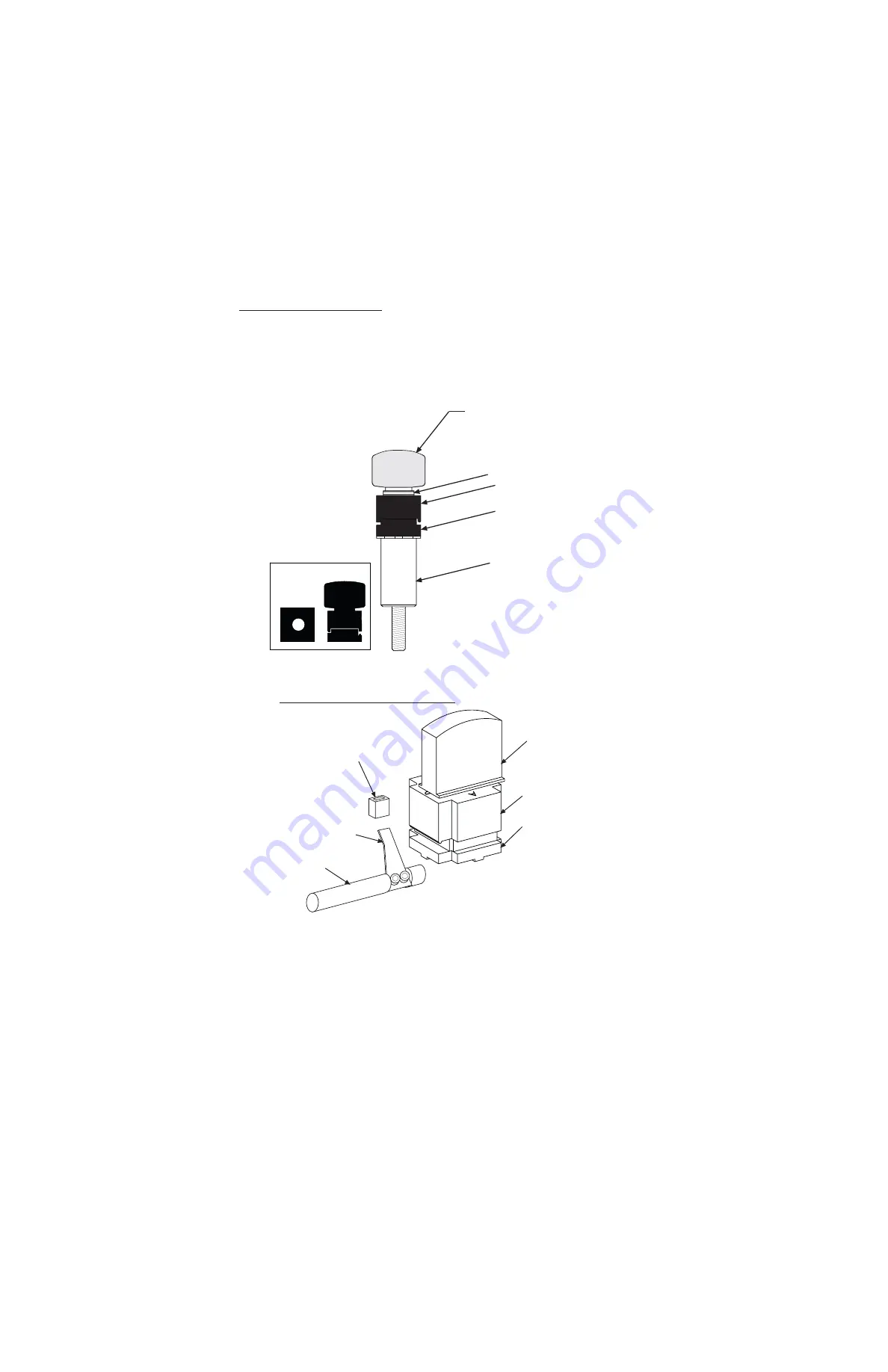

Fig.3

CLAMPS MORE KEYS

NEW 4-WAY VISES

A

B

C

D

RY20080 KNOB WITH SHAFT ASSY.

RY82 3-PC THRUST BEARING ASSY.

RY20089 TOP VISE, JAW 4-WAY

RY20047 BOTTON VISE, 4-WAY

RY20046 VISE PLUNGER