MOTOR MOUNTING HARDWARE

LUBRICATION

UNPLUG YOUR MACHINE PROIR TO LUBRICATION

You do not need to lubricate the motor or the cutter shaft bearings - these ball bearing assemblies

are sealed and lubricated for their lifetime.

Lubricate your machine as often as you like. Use number 30 non-detergent motor oil. Apply oil

with a brush to all black oxide processed steel surfaces. After applying the oil, let it stand overnight

and wipe the oiled parts dry the next day with a clean rag or soft paper towel. Turn the machine

over and lubricate the linkages that drive the carriage shaft left and right.

WARNING:

Do not turn

the machine over and set it on the Power Switch.

SUGGESTION:

When lubricating the stick-shift drive linkages under the machine you might

want to use spray-on bicycle chain lubricant the kind that foams and penetrates.

DO NOT

use

this on the rest of the machine.

Lubricate the vise jaw plungers inside the carriage remove the key clamp knobs and large knurled

knobs and top vise jaws. Squirt some number 30 non-detergent motor oil in the large hold and

reassemble.

DO NOT LUBRICATE

your key machine with LPS-1 or WD-40 in place of number 30 non-

detergent motor oil. You may use LPS-1 or WD-40 as a rust preventative in addition to the number

30 non-detergent motor oil. If you only use LPS-1 or WD-40 as your machines only lubricant you

will eventually damage the machine. These lubricants act more like solvents than lubricants

they work partially as a solvent that extracts already existing oils from bearings and other parts and

redistributes this existing oil along the surfaces that need oil. Eventually you will exhaust all oil

reserves in the machines parts and the machine will be operating as an oil-dry machine.

DO NOT

allow any oil or grease to get on the machines drive belt or pulleys. When handling these

parts be sure your hands are clean and free of any lubricants.

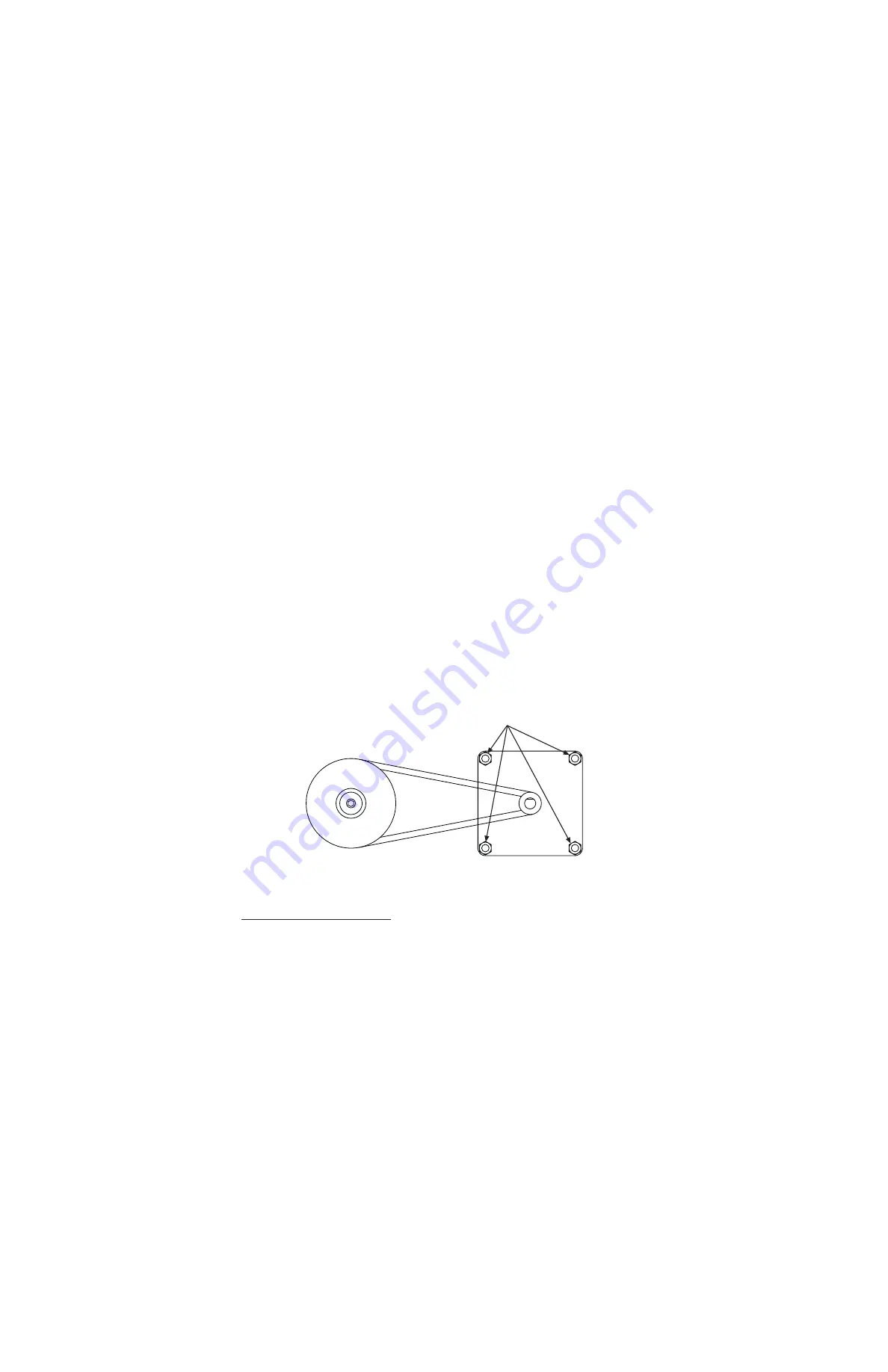

DRIVE BELT

Your machines belt tension is maintained by means of moving the motor. To adjust the belt tension

- use your 7/16 Wrench and your 3/16 Allen Hex Wrench to loosen the four cap screws and hex

nuts securing the motor to the motor bracket. Push the motor hard against the belt and tighten the

four screws.

KEY MACHINE ACCURACY

Generation Cutting

Generation cutting is a process where the key machine operator takes a fresh cut key and duplicates another

key off of it, then takes that freshly cut key and duplicates another from it, and so on. The idea is to cut as

many generations as possible and still have a working key. This is interpreted as a test of the quality of

the key machine.

17