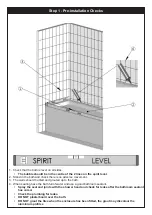

Step 1 - Pre-installation Checks

1. Check that the bath is level on all sides.

• The bubble should be in the centre of the 2 lines on the spirit level.

2. Stand in the bath and check there is no adverse movement.

3. The walls should be tiled and grouted up to the bath.

4. When sealing have the bath full of water and use a good bathroom sealant.

• Spray the seal and joints with the shower head and check for leaks after the bathroom sealant

has cured.

• Check the plumbing for leaks.

• DO NOT plasterboard over the bath.

•

DO NOT grout the tiles when the enclosure has been fitted, the grout may discolour the

aluminium profiles

①

②

③

④