Fine-tuning the Cutting Conditions

You can accurately set items such as the blade force, movement speed, and blade offset to match the nature of

the media and the shape to cut. First, perform a cutting test, and then determine and enter the setting values.

After entering the setting values, perform a cutting test again and check the results. Repeat the process of per-

forming a cutting test and making the settings several times to find the optimal setting values.

Procedure

1.

Close the front cover.

2.

Press [

◀

], [

▶

], [

▲

], or [

▼

] to move the cutting carriage to the location where you want to carry out the cutting test.

You can freely set the location for the cutting test.

3.

Press [FUNCTION].

4.

Press [

▼

] several times to display the screen shown below.

FUNCTION

CUT CONFIG

5.

Press [

▶

] to display the screen shown below.

CUT CONFIG

TEST CUT

6.

Press [ENTER].

The test pattern is cut.

7.

When the cutting of the test pattern is finished, press [

▼

].

8.

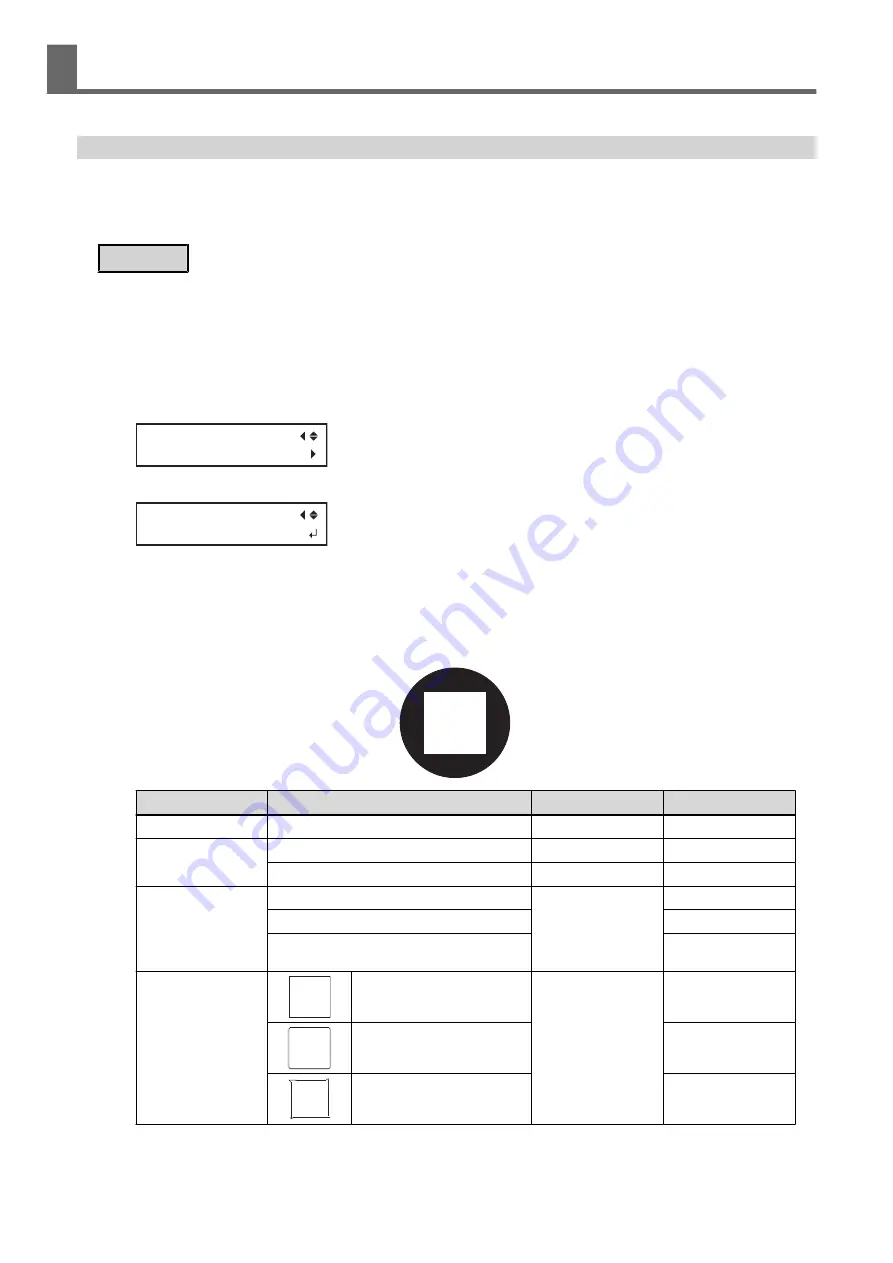

Check the results of the cutting test.

Check item

Result

Setting item

Adjustment

Check the shape.

The cut shape is distorted.

SPEED

Reduce

Peel off the circle.

The square also peels off.

FORCE

Increase

Some uncut areas remain.

SPEED

Reduce

Peel off the square.

The blade leaves faint traces on the backing paper.

FORCE

No change

The blade trace is indistinct.

Increase

The blade trace is too deep and cuts into the back-

ing paper.

Reduce

Check the shape of the

square you have peeled

off.

The corners are not rounded and

do not have "horns."

Offset

No change

The corners are rounded.

Increase

The corners have "horns."

Reduce

9.

Press [

▲

] or [

▼

] to select the cutting condition you want to set.

Accurately Adjusting the Cutting Settings

1. Optimizing the Output Quality

163

Summary of Contents for TrueVIS VG2-540

Page 9: ...Chapter 1 Basic Handling Methods 8 ...

Page 36: ...Setup of Media 2 Basic Operations 35 ...

Page 43: ...Setup of Media 42 2 Basic Operations ...

Page 60: ...Ink Pouch TR2 Cleaning Liquid Pouch Replacement 2 Basic Operations 59 ...

Page 61: ...Chapter 2 Output Method 60 ...

Page 70: ...REDO ADJ YES DONE 10 Press ENTER to confirm your entry Printing Output 1 Printing Method 69 ...

Page 138: ...Chapter 3 Optimizing Quality and Efficiency 137 ...

Page 195: ...W1100mm B Adjusting the Output start Location 194 2 Optimizing Work Efficiency ...

Page 217: ...Chapter 4 Maintenance 216 ...

Page 272: ...Chapter 5 Troubleshooting Methods 271 ...

Page 305: ...Chapter 6 Appendix 304 ...

Page 308: ...8 Detach the blade holder Preparing to Move the Machine 1 Operations When Moving the Unit 307 ...