94

3

Maintenance

3

Maintenance

If Colors Are Uneven

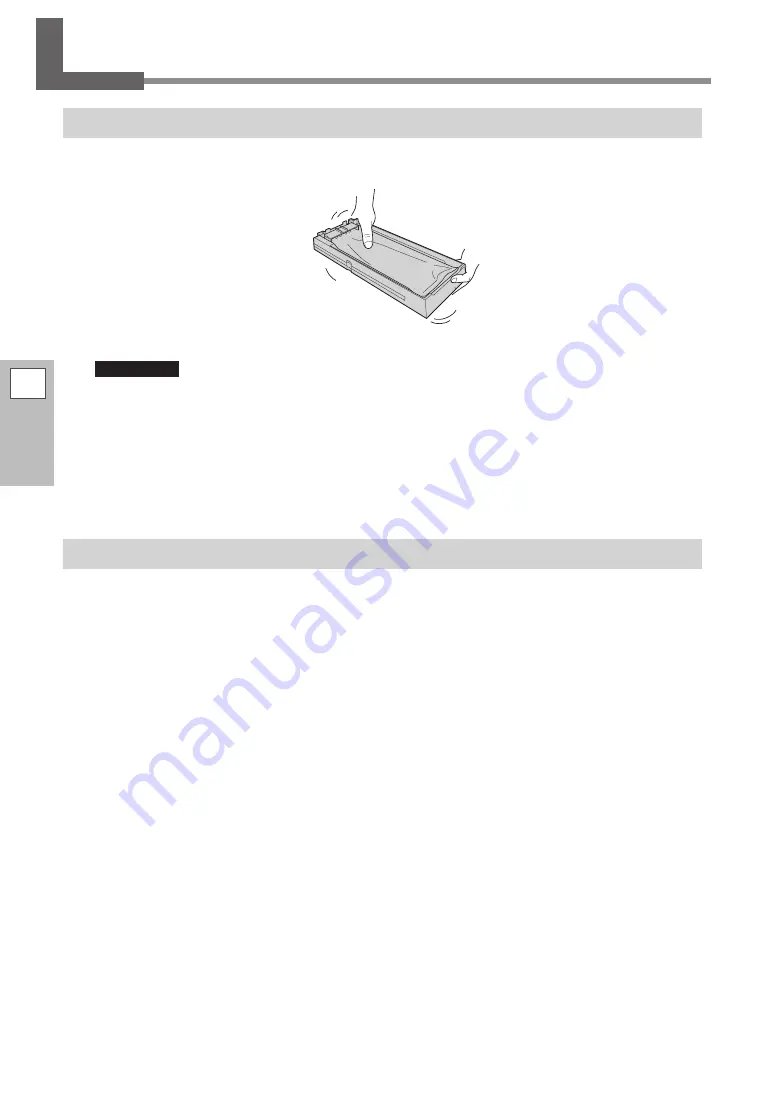

Mixing the Ink by Shaking the Pouch Tray

If ink components precipitate in the ink pouch, colors may be uneven (unevenness in printed colors). If colors

are uneven, remove the pouch trays, and then shake them gently.

Important

• Do not remove the ink pouches. Shake the entire pouch tray. Removing the ink pouches may lead to

the ink leaking.

• Before shaking an ink pouch, wipe off any ink from around the mouth of the ink pouch. If you do not

wipe off the ink, it may splatter when you shake the pouch tray.

• When you have finished mixing the ink, reinsert the pouch tray immediately. If you take time to reinsert

the ink tray, the ink trays will be adversely affected.

If Colors Are Still Uneven

If uneven color issues are not resolved even after shaking the pouch trays, perform super cleaning.

"