206

Rockwell Automation Publication 35-UM001A-EN-P - May 2022

Chapter 10 Maintenance and Repair

Test for Hazardous Voltage

Before servicing the Armor PowerFlex drive or any device in the motor side

(motor, motor cables, motor brake, and so on), follow these steps to remove

power from the Armor PowerFlex and test for hazardous voltage:

1. Remove power from the drive by setting the local disconnect to the Off

position or by removing the three-phase power using the isolating device

upstream (system circuit breaker, for example).

2. After power has been removed from the drive, wait three minutes so the

DC bus capacitors can discharge.

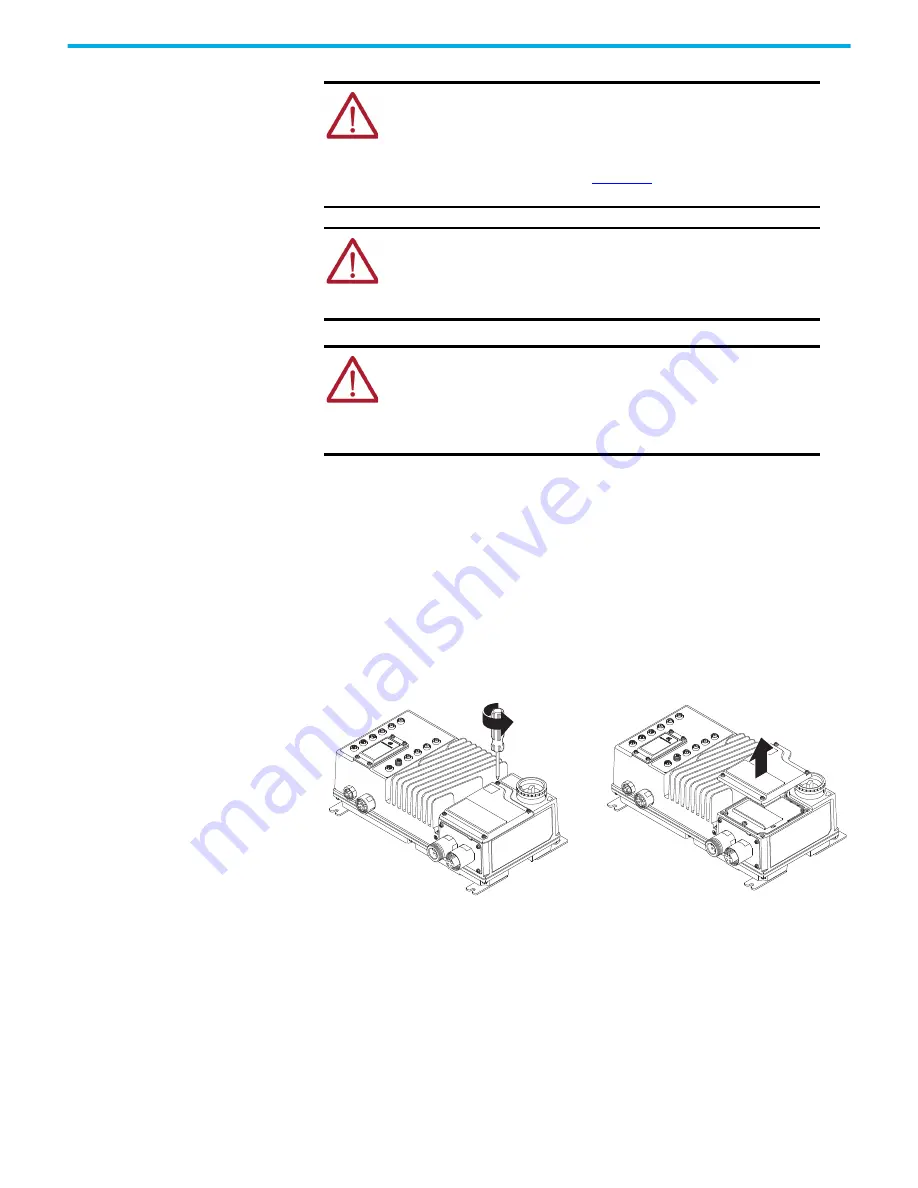

3. After 30 seconds, loosen the screws to remove the power section door.

ATTENTION:

This drive contains electrostatic discharge (ESD) –

sensitive parts and assemblies. Static control precautions are required

during installation, test, service, or repair of this assembly. Component

damage can result if ESD control procedures are not followed. If you are

not familiar with static control procedures, see Guarding against

Electrostatic Damage, publication

, or any other applicable

ESD protection handbook.

ATTENTION:

An incorrectly applied or installed drive can result in

component damage or a reduction in product life. Wiring or application

errors, such as undersized motor, incorrect or inadequate AC supply, or

excessive ambient temperatures can result in malfunction of the

system.

ATTENTION:

Five test points on Armor PowerFlex allow you to confirm

that the products downstream from the drive have been successfully

isolated from hazardous voltage and that hazardous stored energy in

the DC bus has been discharged.

This will allow safer servicing for the electromechanical brake fuses, the

motor output cable, and the motor.