16

XM Dynamic Measurement Module Terminal Base

Publication

ICM-IN003D-EN-P - March 2013

5. Position the terminal base unit up tight against the neighboring

terminal base; make certain the hook on the terminal base slides under

the edge of the terminal base unit.

6. Gently push the side connector into the side of the neighboring

terminal base to complete the backplane connection.

7. Secure the terminal base to the wall with two #6 self-tapping screws.

Wiring

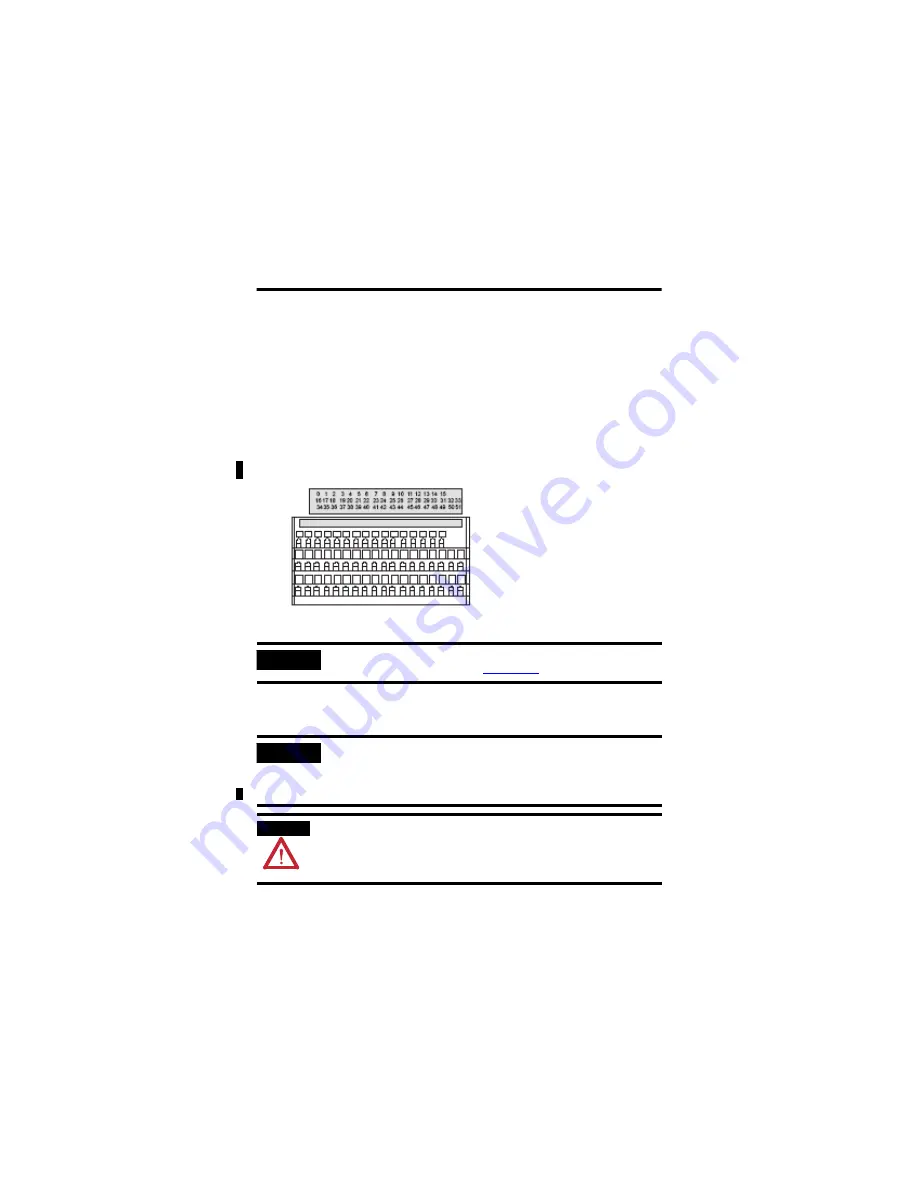

Terminal Assignments

IMPORTANT

For more wiring connection information, see the XM Dynamic Measurement

Module User Manual, publication

IMPORTANT

The terminal block assignments are different for different terminal base

units. The following table applies only to the 1440-TBS-J. Refer to the

installation instructions for the specific terminal base unit for its terminal

assignments.

WARNING

If you connect or disconnect wiring while the field-side power is on, an

electrical arc can occur. This could cause an explosion in hazardous location

installations. Be sure that power is removed or the area is nonhazardous

before proceeding.

1440-TBS-J