SECTION 10: O

UTSIDE

A

IR

S

UPPLY

43 of 83

SECTION 10: OUTSIDE AIR SUPPLY

The CRV-Series system is appro

v

ed for

u

se

w

ith an

o

u

tside air system. Halogenated hydrocarbons or

other corrosi

v

e chemicals in the air can be dra

w

n into

the eq

u

ipment and serio

u

sly damage the system

components. A

v

oid the

u

se of s

u

ch chemical

compo

u

nds near the air inlet to the heaters.

IMPORTANT:

If the b

u

ilding has a slight negati

v

e

press

u

re or corrosi

v

e contaminants are present in the

air, an o

u

tside comb

u

stion air s

u

pply to the heater is

req

u

ired.

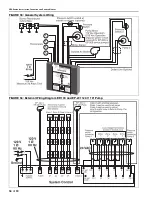

All joints and seams in the air s

u

pply system m

u

st be

airtight. Attach the filter ho

u

sing to the b

u

rner

assembly

u

sing the

w

ing n

u

t pro

v

ided.

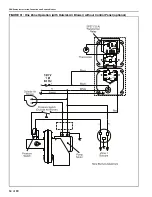

10.1 Pressurized

See Page 46, Figure 26

for a typical layo

u

t of a

press

u

rized air s

u

pply system.

For press

u

rized o

u

tside air s

u

pplies, the o

u

tside air

blo

w

er motor has a press

u

re s

w

itch that m

u

st be

u

sed. Wire this s

w

itch in series

w

ith the p

u

mp

press

u

re s

w

itch. When

u

sing an o

u

tside air blo

w

er

w

ith a ROBERTS GORDON

®

System Control or

ROBERTS GORDON

®

ULTRAVAC

™

control or relay

transformer, a separate load relay package is

req

u

ired. Wire the control for the relay in parallel

w

ith

the p

u

mp. The o

u

tside air blo

w

er m

u

st ha

v

e a

separate 20 A, 120 V po

w

er s

u

pply.

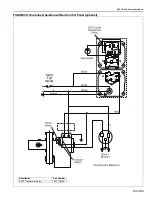

See Page 44,

Figure 23

for o

u

tside air blo

w

er internal

w

iring

req

u

irements. The o

u

tside air blo

w

er has an

adj

u

stable internal damper that sho

u

ld be

w

ide open.

On smaller systems (abo

u

t 3 b

u

rners) this damper

might need to be closed

u

p to half

w

ay if the press

u

re

s

w

itch does not make.

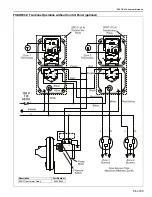

10.2 Non-Pressurized

For a non-press

u

rized o

u

tside air s

u

pply, a 4" (O.D.)

single

w

all pipe d

u

ct may be attached to the b

u

rner

and end

v

ent. For length and d

u

ct sizing

req

u

irements, see d

u

ct design r

u

les in

Figure 22

. To

pre

v

ent condensation, ins

u

late the o

u

tside air d

u

ct.

CAUTION

Product Damage Hazard

Do not use heater in area containing

corrosive chemicals.

Refer to appropriate Material Safety Data

Sheets (MSDS).

Failure to follow these instructions can result

in product damage.

Summary of Contents for CoRayVac CRV-B-10

Page 2: ......

Page 4: ......

Page 6: ......

Page 71: ...SECTION 13 STARTING THE SYSTEM 65 of 83 FIGURE 42 Vacuum Reading ...

Page 81: ...SECTION17 TROUBLESHOOTING 75 of 83 17 1 Troubleshooting Flow Chart ...

Page 90: ......

Page 91: ......

Page 92: ......

Page 93: ......

Page 94: ......