Rhein - Nadel Automation GmbH

4

Date: 14.04.2014

VT-BA-GL-GB

2 Safety instructions

The conception and production of our linear feeders has been carried out very carefully, in order to guarantee

trouble-free and save operation. You too can make an important contribution to job safety. Therefore, please read

this short operating instruction completely, before starting the machine. Always observe the safety instructions!

Make sure that all persons working with or at this machine carefully read and observe the following safety

instructions!

This operating instruction is only valid for the types indicated on the front page.

Notice

his hand points to information that gives you useful tips for the

operation of the linear feeder.

Attention

This warning triangle marks the safety instructions. Non-observance of these warnings can result in

serious or fatal injuries!

Dangers occuring at the machine

Make sure that the protector ground of the electric power supply is in perfect condition!

Operation of the linear feeder without trim panel is strictly prohibited!

Proper use

The intended use of the linear feeder is the actuation of conveying tracks. These are used for linear transport and

feeding of correctly positioned mass-produced parts, as well as for the proportioned feeding of bulk material.

The intended use also includes the observance of the operating and servicing instructions.

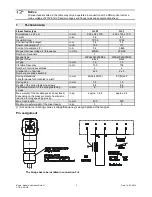

Please take the technical data of your linear feeder from the table "technical data" (see chapter 1). Make sure that

the connected load of the linear feeder, control unit and power supply is compatible.

Notice

The linear feeder may only be operated in perfect condition!

The linear feeder may not be operated in the explosive or wet area.

The linear feeder may only be operated in the configuration drive unit, control unit and oscillating unit, as specified

by the manufacturer.

No additional loads may act upon the linear feeder, apart from the material to be transported, for which the special

type is designed.

Attention

It is strictly prohibited to put any safety devices out of operation!

Demands on the user

For all activities (operation, maintenance, repair, etc.) the details of the operating instructions must be observed.

The operator has to avoid any working method which would impair the safety of the linear feeder.

The operator must take care that only authorized personnel works at the linear feeder.

The operator is obliged to inform the operator immediately about any changed conditions at the linear feeder that

could endanger safety.

Attention

The linear feeder may only be installed, put into operation and serviced by expert personnel.

The