- 21 -

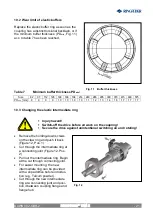

Fig. 12

Fig. 11 Buffer thickness

10.2 Wear limit of elastic buffers

Replace the elastic buffer ring as soon as the

coupling has a distinct torsional backlash, or if

the minimum buffer thickness (PD

min

, Fig. 11)

acc. to table 7 has been reached.

Table 7

Minimum buffer thickness PD

min

:

Size

82

97 112 128 148 168 194 214 240 265 295 330 370 415 480 575

PD

min

[mm] 8

9

9

9

10

10

10

10

11

12

13

14

16

17

17

17

10.3 Changing the elastic intermediate ring

Injury hazard!

Switch-off the drive before all work on the coupling!

Secure the drive against unintentional switching on and rotating!

Remove the holding-down screws

on the claw ring and push it back

(Figure 12, Pos. 1)

Cut through the intermediate ring at

a connecting joint (Figure 12, Pos.

2)

Pull out the intermediate ring. Begin

at the cut through connecting joint.

For easier mounting, the new

intermediate ring can be provided

with a slip additive before introduc-

tion (e.g. Talcum powder).

Cut through the new intermediate

ring at a connecting joint and posi-

tion it between coupling flange and

flange hub.

RINGFEDER

®

TNM E

BAWN 002-GBR-2