20068118

20

GB

Technical description of the burner

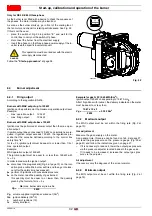

4.14 Servomotors (SQN13...)

Introduction

The servomotors that equip the burners of the

RS

range work di-

rectly on the air damper and the gas butterfly valve, without me-

chanical leverages but via the interposition of an elastic coupling.

They are commanded by the control box, which constantly

checks their position by means of a return signal from the optic

sensor inside the servomotor.

Important notes

All interventions (assembly and installation operations,

assistance, etc.) must be carried out by qualified personnel.

Before modifying the wiring in the servomotor connection

area, fully disconnect the burner control device from the

power supply (omnipolar separation)..

To avoid the risk of electrocution, protect the connection ter-

minals in a suitable manner and correctly fix the cover.

In the event of assembly, installation, maintenance, etc... it is

necessary to check that the wiring and the parameterisation

are in order.

Falls and collisions can negatively affect the safety func-

tions. In this case, the unit must not be operated, even if it

displays no evident damage.

Installation notes

Check the relevant national safety standards are respected.

The connection between the actuator command shaft and

the control element must be rigid, without any mechanical

play.

The tightening torque for the fixing screws should be 1.5 Nm.

It is recommended that this value is not exceeded to prevent

damaging the servomotor.

To avoid an excessive load on the bearings due to rigid

hubs, the use of compensation clutches without any

mechanical play is recommended (e.g. metal bellows-type

clutches).

It is advisable to oversize the drive shaft in relation to the

rated torque of the actuator.

The static torque is reduced when the electrical supply of the

actuator is switched off.

Arrange the H.V. ignition cables separately, as far as possi-

ble from the control box and the other cables.

Technical data

Tab. I

WARNING

To avoid accidents, material or environmental

damage, observe the following instructions!

Avoid opening, modifying or forcing the servo-

motor. The servomotor is equipped with a system

of optical feedback.

Power supply

AC / DC 24 V ± 20% (load inter-

face)

Safety class

EN 60730 part 1-14

Power absorption

Max. 7.5 W

Angle adjustment, usable

range

Max. 90°

Degree of protection

IP40

Work of field

0-90°

Opening time 0-90°

Min 5 sec.

Max 120 sec. depending on the

control box type

Direction of rotation

Anticlockwise

Torque operating

0.7 Nm

Torque off

0.4 Nm

Cable length

1.2 m

Radial load on the bearing

30 N

Axial load on the bearings

Max. 5 N

Weight

About 0.3 kg

Connecting cable

RAST2.5

Environmental conditions:

Operation

Climatic conditions

Mechanical conditions

Temperature range

Humidity

DIN EN 60721-3-3

Class 3K3

Class 3M3

-10 ... +60 °C

< 95% RH

WARNING

Condensation, formation of ice and the entrance

of water are not permitted!

Fig. 10

D8083

Summary of Contents for RS 25/E BLU Series

Page 2: ...Translation of the original instructions...

Page 65: ...63 20068118 GB Appendix Electrical panel layout RS 25 E BLU...

Page 66: ...20068118 64 GB Appendix Electrical panel layout RS 35 E BLU...

Page 67: ...65 20068118 GB Appendix Electrical panel layout RS 35 E BLU 3Ph...

Page 68: ...20068118 66 GB Appendix Electrical panel layout RS 25 35 E BLU...

Page 69: ...67 20068118 GB Appendix Electrical panel layout RS 35 E BLU 3Ph...

Page 70: ...20068118 68 GB Appendix Electrical panel layout...

Page 71: ...69 20068118 GB Appendix Electrical panel layout...

Page 72: ...20068118 70 GB Appendix Electrical panel layout...

Page 73: ...71 20068118 GB Appendix Electrical panel layout...

Page 75: ......