2374

1

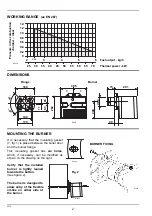

TECHNICAL DATA

O

The burner meets protection level of IP 40, EN 60529.

O

Burner with CE marking in conformity with EEC Directives: Machine Directive 2006/42/EC, Low Voltage

Directive 2006/95/EC and Electromagnetic Compatibility 2004/108/EC

.

TYPE

459T55

Thermal power – output

29 – 69 kW

–

2.45 – 5.8 kg/h

Fuel

Kerosene, viscosity 1.5 – 6 mm

2

/s at 20 °C

Light oil, max. viscosity

6 mm

2

/s at 20 °C

Electrical supply

Single phase,

230 V

±

10%

~

50Hz

Motor

Run current 0.85 A – 2850 rpm – 298 rad/s

Capacitor

4

F

Ignition transformer

Secondary 8 kV – 16 mA

Pump

Maximum pressure 14 bar (203 psi)

Absorbed electrical power

0.16 kW

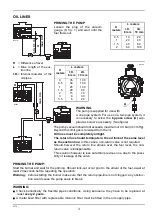

1

– Return line

2

– Suction line

3

– Gauge connection

4

– Pump pressure regulator

5

– Lock-out lamp and reset button

6

– Screws fixing air-damper

7

– Flange with insulating gasket

8

– Vacuum gauge connection

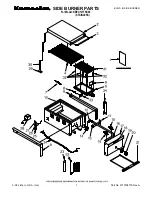

EQUIPMENT

Quantity

Description

1

1

1

2

2

1

Flange with insulating gasket

Screw of by-pass pump

Screw with two nuts for flange

Screws

Screws with washer, nuts

Flexible pipe with nipple

8

D5534

Fig. 1

1

2

3

4

5

6

6

7