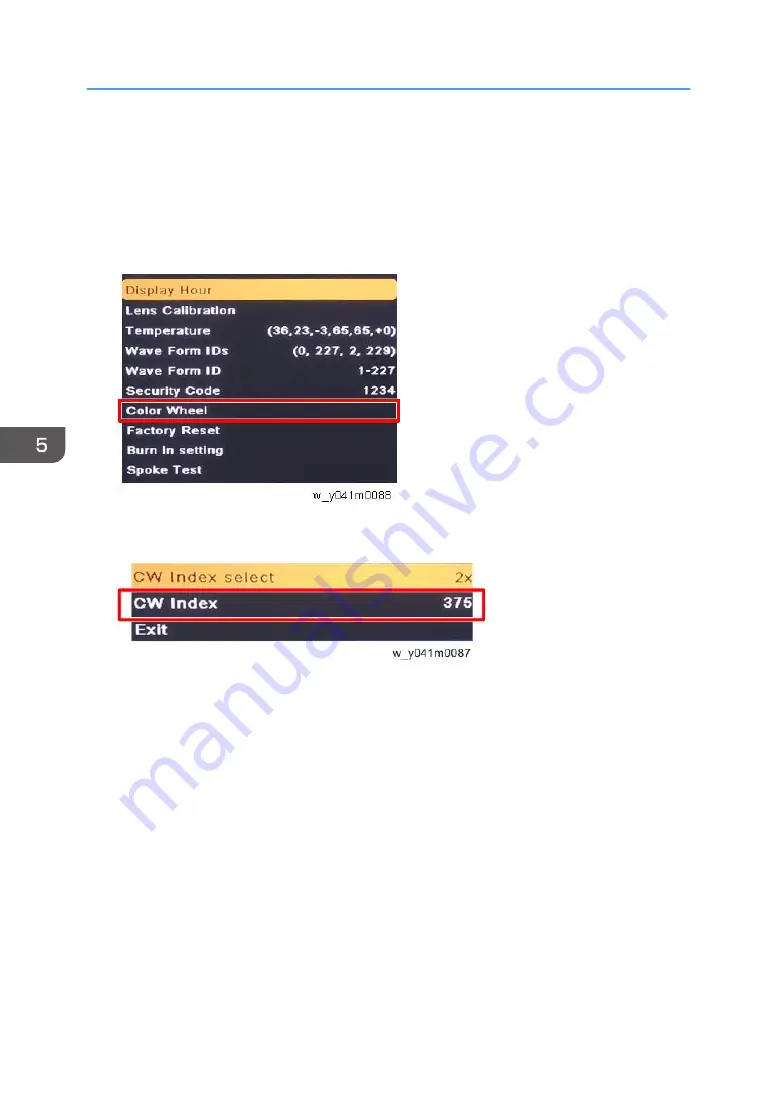

Color Wheel Index

After replacing the main board or color wheel, "Color Wheel Index" should be done.

1.

page 95 "How to enter the Engineering Mode"

)

2.

Select "Color Wheel", and then press the "Enter" key.

3.

Select "CW Index ", then use the "Left" or "Right" keys to adjust the color balance of the

projected image.

5. Test & Inspection

104

Summary of Contents for Deneb-PJ2 Y068

Page 1: ...Deneb PJ2 Machine Codes Y068 Y069 Field Service Manual 20 January 2015...

Page 2: ......

Page 23: ...Diagram Diagram 21...

Page 24: ...1 Product Information 22...

Page 41: ...4 Remove the 1 screw to remove the LAN board A 5 Remove the 3 hex screws Part Replacement 39...

Page 56: ...Optical Engine 1 Remove the 12 screws 3 Replacement and Adjustment 54...

Page 65: ...4 Remove the 3 adjustable feet A and nuts B from the bottom cover C Part Replacement 63...

Page 74: ...Main Procedures 4 Troubleshooting 72...

Page 76: ...Error LED flashing red temp LED steady lights red 4 Troubleshooting 74...

Page 77: ...Error LED flashing red temp LED flashing red Main Procedures 75...

Page 78: ...Error LED flashing red lamp LED steady lights red 4 Troubleshooting 76...

Page 79: ...Error LED flashing red filter LED flashing red Main Procedures 77...

Page 81: ...1 2 Is the PC image displayed on the screen Main Procedures 79...

Page 82: ...1 3 Is video image displayed on the screen 4 Troubleshooting 80...

Page 83: ...1 4 Is focus ok Main Procedures 81...

Page 84: ...1 5 Is color ok 4 Troubleshooting 82...

Page 85: ...1 6 Have line bar Main Procedures 83...

Page 86: ...1 7 Is there noise on the image 4 Troubleshooting 84...

Page 87: ...1 8 Is uniformity ok Main Procedures 85...

Page 88: ...D Remote Control Troubleshooting 4 Troubleshooting 86...

Page 89: ...Main Procedures 87...

Page 90: ...E Network Troubleshooting 1 1 Is the LAN connector LED in normal status 4 Troubleshooting 88...

Page 91: ...1 2 Are the network settings of the unit right Main Procedures 89...

Page 94: ...Item Error Log Explanation Related parts 11 x 4 I2CFail THERMAL SENSOR MB 4 Troubleshooting 92...

Page 110: ...5 Test Inspection 108...

Page 127: ...3 Check the serial number Re write Serial Number 125...

Page 128: ...MEMO 126...

Page 129: ...MEMO 127...

Page 130: ...MEMO 128 EN...