MECHANISM OVERVIEW

SM 6-5

C249

Detailed

Des

cription

s

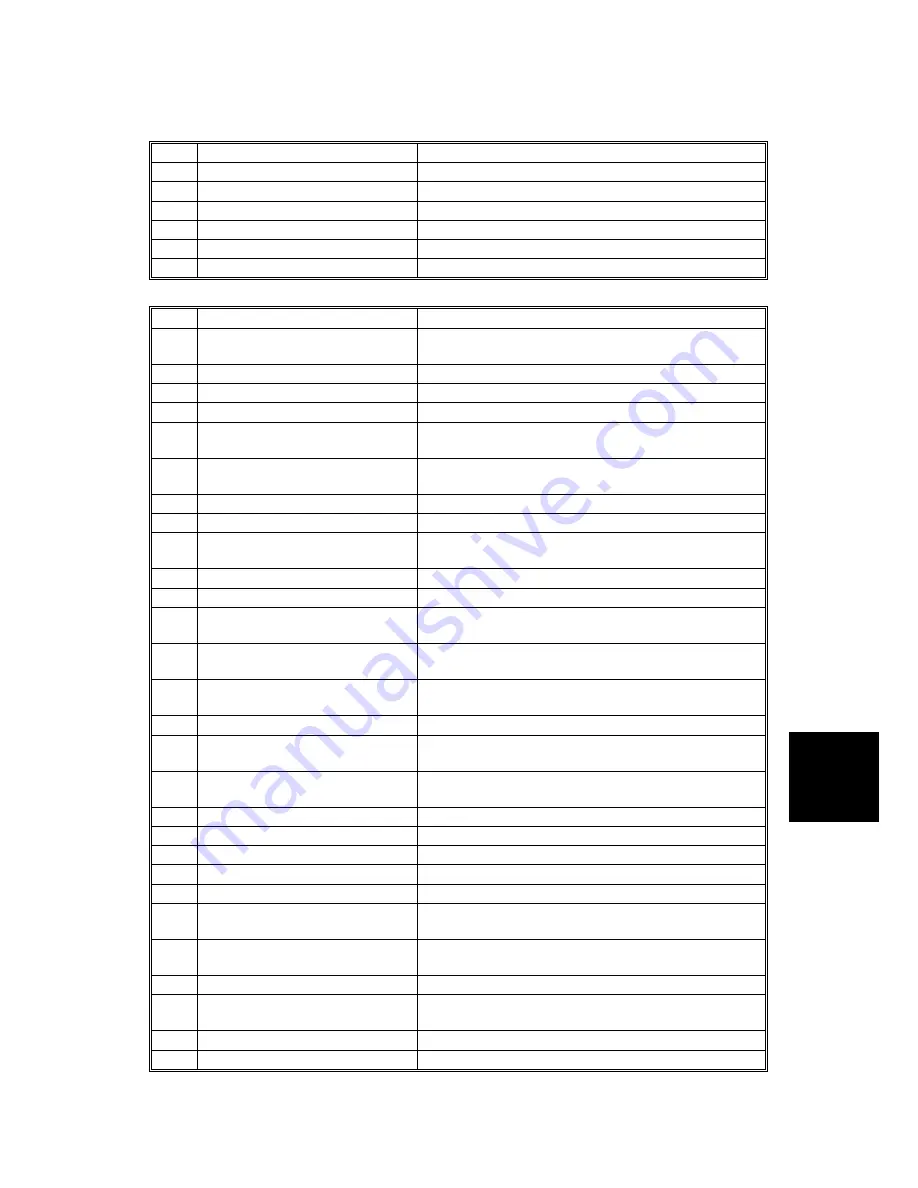

Switches

No. Component

Function

19

Table Lowering Switch

Lowers the paper table.

24

Door Safety Switch

Checks whether the front door is properly closed.

27

Main Switch

Turns the power on or off.

13

Master Making Unit Set Switch Checks if the master making unit is installed.

37

Eject Box Set Switch

Checks if the master eject box is installed.

62

Lower master tray set switch

Checks if the lower master tray is installed.

Sensors

No. Component

Function

53

Master Eject Position (Drum

HP) Sensor

Detects when the drum is at the master eject

position.

54

Paper Exit Timing Sensor

Determines the paper exit misfeed check timing.

52

Feed Start Timing Sensor

Determines the paper feed start timing.

30 Master

Eject

Sensor

Detects used master misfeeds.

32

Pressure Plate Limit Sensor

Detects when the pressure plate is in the lowest

position.

31

Pressure Plate HP Sensor

Detects when the pressure plate is at the home

position.

34

Drum Master Sensor

Detects if there is a master on the drum.

38

Paper Exit Sensor

Detects paper misfeeds at the exit.

55

2nd Feed Timing Sensor

Determines the paper misfeed check timing at the

paper registration area.

44

Clamper Open Sensor

Detects if the clamper is in the open position.

45

Clamper Closed Sensor

Detects if the clamper is in the closed position.

49

Table Lower Sensor

Detects when the paper table is at its lower limit

position.

2

Platen Cover Sensor

Detects whether the platen cover is open or

closed.

1

Scanner HP Sensor

Detects when the image sensor is at home

position.

9

Master Set Cover Sensor

Checks if the master set cover is properly set.

10

Master End Sensor

Detects when the master making unit runs out of

master roll.

14

Paper Height Sensor

Detects when the paper table reaches the paper

feed position.

18

Registration Sensor

Detects paper approaching the registration roller.

17

Paper End Sensor

Detects when the paper table runs out of paper.

6

Cutter HP Sensor

Detects when the cutter is at the home position.

16

Paper Length Sensor

Detects when long paper is on the paper table.

56

2nd drum master sensor

Detects if there is a master on the drum.

58

Printing pressure HP sensor

Detects when the printing pressure is at the home

position.

60

Duct plate HP sensor

Detects when the duct plate is at the home

position.

62

Duct jam sensor

Detects when a master remains in the duct.

65

Thermal head HP sensor

Detects when the thermal head is at the home

position.

68

Master edge sensor

Detects the leading edge of the master.

70

Ink idling roller HP sensor

Detects when the idling roller is at home position.

Summary of Contents for C249

Page 1: ...C249 C264 SERVICE MANUAL 001780MIU...

Page 2: ......

Page 3: ...C249 C264 SERVICE MANUAL...

Page 4: ......

Page 5: ...C249 C264 SERVICE MANUAL 001780MIU...

Page 6: ......

Page 8: ......

Page 10: ......

Page 12: ......

Page 18: ...C249 C264 vi SM PRINTER SCANNER C624 SEE SECTION C624 FOR DETAILED TABLE OF CONTENTS...

Page 20: ......

Page 21: ...INSTALLATION...

Page 22: ......

Page 45: ...PREVENTIVE MAINTENANCE...

Page 46: ......

Page 49: ...REPLACEMENT AND ADJUSTMENT...

Page 50: ......

Page 96: ......

Page 97: ...TROUBLESHOOTING...

Page 98: ......

Page 114: ......

Page 115: ...SERVICE TABLES...

Page 116: ......

Page 145: ...DETAILED DESCRIPTIONS...

Page 146: ......

Page 208: ......

Page 209: ...SPECIFICATIONS...

Page 210: ......

Page 215: ...C264...

Page 216: ......

Page 224: ......

Page 239: ...INSTALLATION PROCEDURE SM 1 13 C264 C264 Installation Procedure 1 Remove the strips of tape...

Page 261: ...SCANNER SM 3 5 C264 C264 B SBU x 1 x 5 C Lamp stabilizer x 2 x 5 B C...

Page 322: ......

Page 354: ......

Page 358: ...MECHANISM OVERVIEW C267 6 4 SM 62 60 61 64 65 66 67 63 69 70 68 71 72...

Page 409: ...TIMING CHART SM 6 55 C264 C264 6 11 TIMING CHART 6 11 1 MASTER EJECTION...

Page 425: ...DOCUMENT FEEDER C600...

Page 426: ......

Page 428: ......

Page 446: ......

Page 447: ...PRINTER CONTROLLER C624 SERVICE MANUAL PARTS CATALOG...

Page 448: ......

Page 450: ......

Page 483: ...C624 PARTS CATALOG...

Page 484: ......