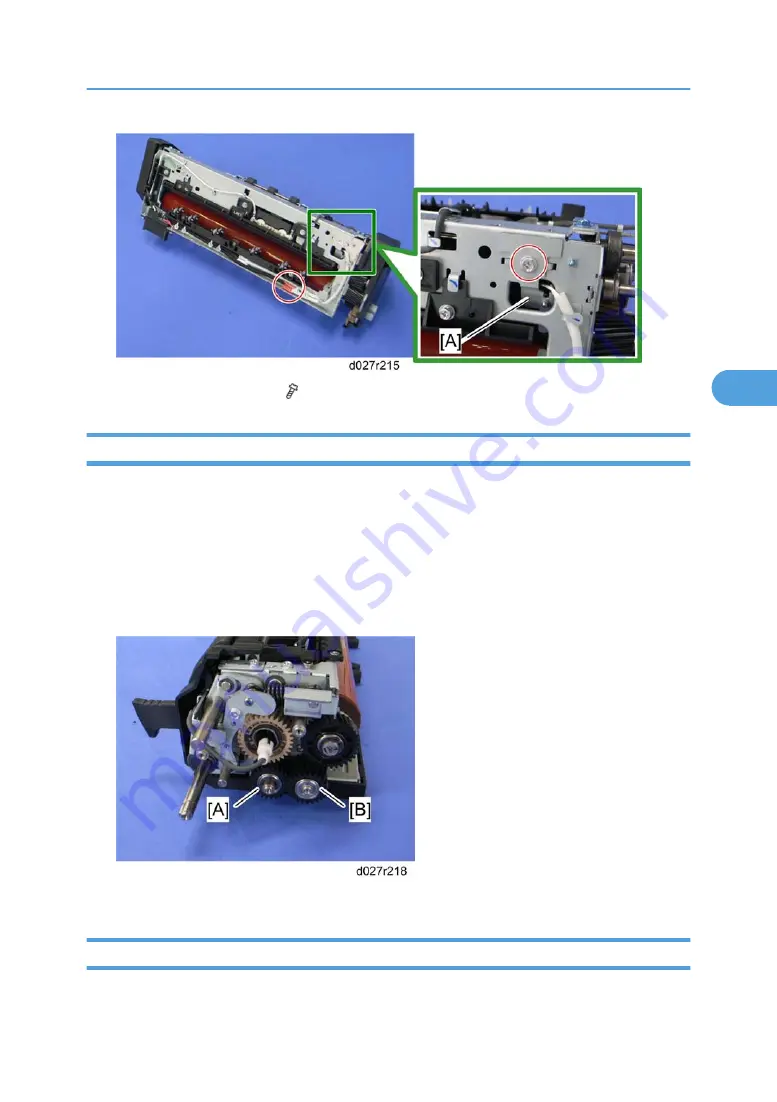

4. Pressure roller thermistor [A] ( x 1)

Bearing Gear and Idle Gear

1. Fusing unit (

*

2. Rear fusing cover (

*

p.174 "Heating Roller and Heating Roller Bearing")

3. Pressure roller contact shaft actuator and pressure roller contact shaft gear (

*

4. Rear bracket (

*

p.174 "Heating Roller and Heating Roller Bearing")

5. Fusing lamp rear bracket (

*

6. Bearing gear [A] (c-ring x 1) and idle gear [B]

Fusing Fan

1. Rear cover (

*

Fusing

187

4

Summary of Contents for AP-P2 G188

Page 1: ...Model AP P2 Machine Code G188 G189 Field Service Manual January 2009 Subject to change ...

Page 2: ......

Page 12: ...Electrical Component Defects 253 INDEX 255 10 ...

Page 22: ...1 Product Information 20 1 ...

Page 43: ...Item SP No Function Default Printer Installation 41 2 ...

Page 100: ...3 Preventive Maintenance 98 3 ...

Page 111: ...Left Cover 1 Left cover A x 6 Rear Cover 1 Rear cover A x 6 Exterior Covers 109 4 ...

Page 116: ...2 Filter B 3 Ozone filter C 4 Replacement and Adjustment 114 4 ...

Page 174: ...6 Development clutch K A x 1 4 Replacement and Adjustment 172 4 ...

Page 243: ...Controller Self Diagnostics 241 5 ...

Page 250: ...5 System Maintenance Reference 248 5 ...

Page 256: ...6 Troubleshooting 254 6 ...

Page 257: ...Model AP P2 Machine Code G188 G189 Appendices January 2009 Subject to change ...

Page 258: ......

Page 282: ...1 Appendix Specifications 24 1 ...

Page 286: ...2 Appendix Preventive Maintenance Tables 28 2 ...

Page 358: ...3 Appendix Service Call Conditions 100 3 ...

Page 374: ...5 Appendix Troubleshooting Guide 116 5 ...

Page 383: ...Sensor Locations Jam Detection 125 6 ...

Page 384: ...6 Appendix Jam Detection 126 6 ...

Page 392: ...7 Appendix Electrical Component Defects 134 7 ...