Series SCK, Size 25-25-100

Page 10

9220-003-en

Revision 14

TM 10272

Edition 01/2021

4

Product description

The housing dimensions, nominal ratings and tech-

nical requirements of the pump series SCK corre-

spond to ISO 2858 / DIN EN 22858 / DIN ISO 5199.

The technical requirements of the VDMA 24279 are

satisfied.

The sectional drawing shows the design of the pump.

See

Section 9.2 and 9.3

.

Additional information for the pump is provided in the

brochure.

All components which come into contact with the me-

dium are either plastic-lined or made of other resistant

materials, e.g. silicon carbide.

The pump consists of the assemblies:

Housing, lantern/back plate, impeller, shaft sleeve,

bearing pedestal, shaft gasket and mechanical seal

(separate manual).

4.1 Housing

The metallic shell gives the plastic lining of the hous-

ing

100

the necessary stability.

Optionally, the housing can be fitted with a drain (see

Section 5.4.6

) or heating. This is shown in the data

sheet or in a separate technical document.

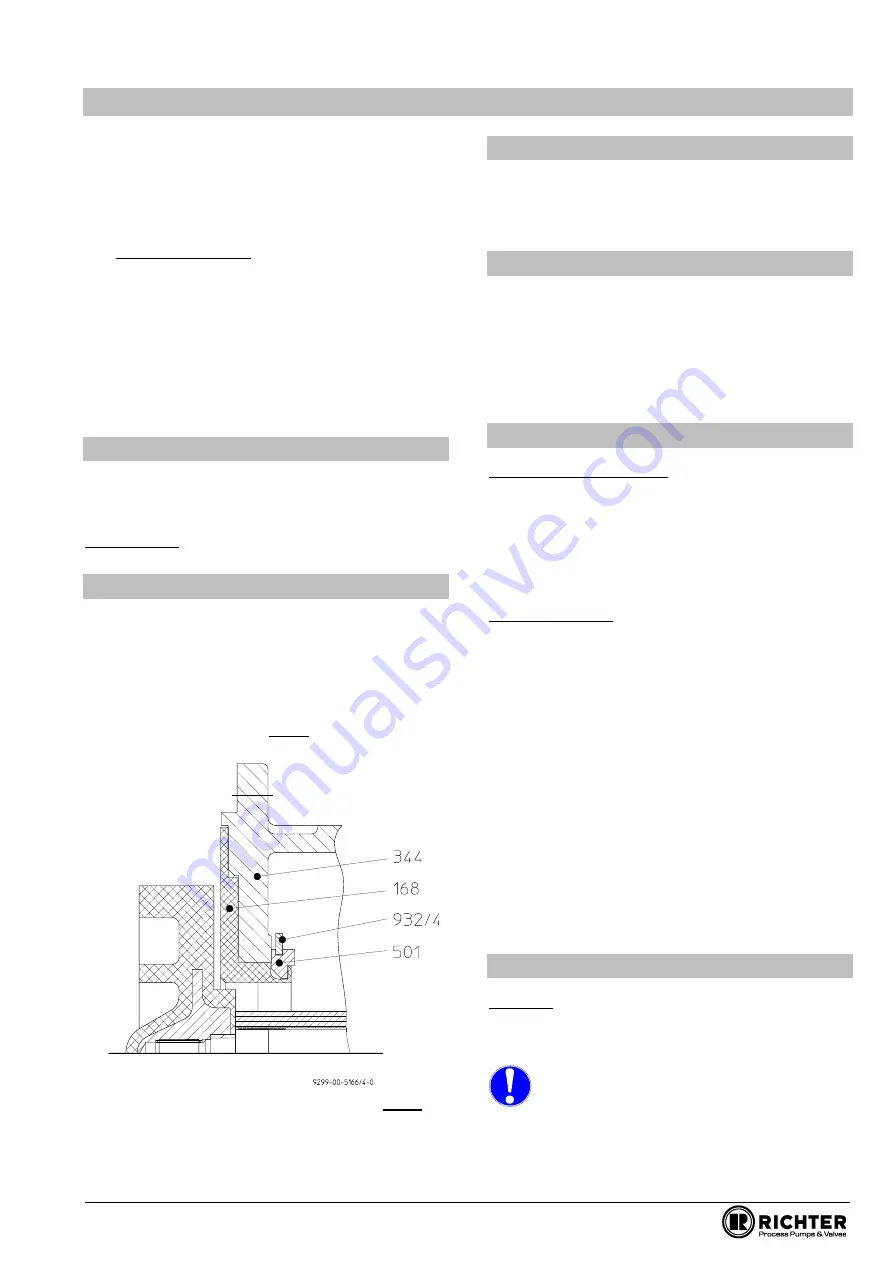

4.2 Lantern with back plate

The replaceable back plate

161

consists of the back

plate insert

168

, a two-piece ring

501

and circlip

932/4

. These parts can also be replaced by the cus-

tomer.

The back plate insert

168

is held in the lantern

344

by

a 2-piece ring

501

. A circlip

932/4

holds the 2-

piece ring together. See

Fig. 2

.

Fig. 1

4.3 Impeller

For strength reasons the impeller

230

has a metallic

core inside with which is it screwed onto the shaft

210

.

A locking unit

930/1

is installed between the impeller

and the shaft as an anti-torsion insert.

4.4 Shaft sleeve

To protect the shaft

210

against corrosion, the section

between the impeller and the shaft gasket is protected

with a shaft sleeve

524

made of a hard, corrosion-

resistant material.

A plastic lining is provided at the bearing points in the

shaft sleeve made of non-metallic materials in order to

permit a safe transition to the metallic shaft.

4.5 Bearing pedestal

Long life grease lubrication

The bearing

321/2

on the motor side is designed as a

fixed bearing and that on the pump side as a floating

bearing

321/1

.

A rear bearing cover

361

is installed on the motor side

as additional protection. Grease is provided between

the rear bearing cover and the bearing as corrosion

protection. An additional seal can be installed.

Oil bath lubrication

The bearing pedestal

330

contains radial ball bearings

321/1, 321/2

, which are lubricated by an oil bath. The

fixed bearing is arranged on the motor side, the

floating bearing on the pump side.

A rear bearing cover

361

, which accomodates a rotary

shaft seal

421/1

and an O-ring

412/1

for oil sealing, is

installed on the motor side.

A so-called spring bushing

546

is installed on the

pump side.

It has several functions:

Any medium emerging from the mechanical seal is

kept away from the bearing.

Cup springs

950/1

, which press the shaft sleeve

524

against the impeller

230

are inserted in order to

seal at that location.

It serves as a running surface when an additional seal

ring is installed.

4.6 Mechanical seals

Designs:

Single mechanical seal external

Double mechanical seal to DIN EN 12756

See the relevant installation and operating

manuals of Richter or the mechanical seal

manufacturer.