20

Survivor

®

SR Siderail Truck Scale Assembly Instrucitons

8.5

Overview and Equipment Required

Load Cell Trimming

Individual

load cell signal trimming (equalizing the signal output from each load cell) must be done first along

each side of the scale so all cells on a side have equal signal output. Adjustments are somewhat interactive, so each

side should be done at least twice.

Once that is done, load cell

pairs

—one from each side—are trimmed as paired sections until each sectional output

is equal. Adjustments to each section should also be done at least twice.

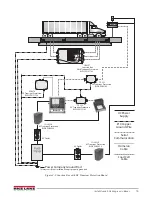

Figure 8-4. Load Cell Trimming Diagram.

Equipment Required

Both of these trimming operations can be done using only a weight cart parked in various locations on the scale.

Final verification of equal output trimming, however, will require test weights to be placed on the deck in various

locations.

8.6

Trimming Individual Cells

Connect all load cells to the summing board terminals in the junction box, and connect the main interface cable

from the junction box to the indicator. Power up the indicator.

Turn all load cell potentiometers (individual and section) in the junction box clockwise until a clicking noise is

heard when you continue turning. This eliminates any initial resistance so all signals are at full strength. You’re

now ready to do

individual signal trimming

.(See j-box summing box instructions for details)

Side 1

The first objective is to adjust individual load cells along one side of the scale for equal signal output when equal

weight is put on those cells. For convenience, that side of the scale will be referred to as Side 1. The trimming

weight you will use will be the loaded weight cart.

1. Park the cart as close as possible to Side 1 being trimmed with the wheels centered over the end load cell

mount (No. 1 in Figure 8-1). Record the indicator reading. Remember that the scale is still uncalibrated, so

the indicator readings are simply raw counts rather than weight units.

Figure 8-5. Trimming Load Cell Number One

2. Move the cart directly over mount No. 2 and record that reading. Move the cart directly over mount No. 3

and record that reading. Move the cart so the wheels are centered directly over mount No. 4 (you may have

to turn the weight cart around so all wheels remain on the scale) and record the reading.

1st – Trim Side 1 Cells (1, 2, 3, 4)

2nd – Trim Side 2 Cells (5, 6, 7, 8)

3rd – Trim Sections

(1,8; 2,7; 3,6; 4,5)

Weight

Cart

1

4

3

2

8

5

6

7

1

4

3

2

8

5

6

7

Summary of Contents for Survivor SR

Page 1: ...SURVIVOR SR Siderail Truck Scale Assembly Instructions 45698 Rev D...

Page 2: ......

Page 29: ......