Chapter 8

8-18

BiPAP Focus Ventilator Service Manual © Respironics, Inc.

REF 1029568 Rev B

Component Removal/Installation

8.11 Interconnect

Diagrams

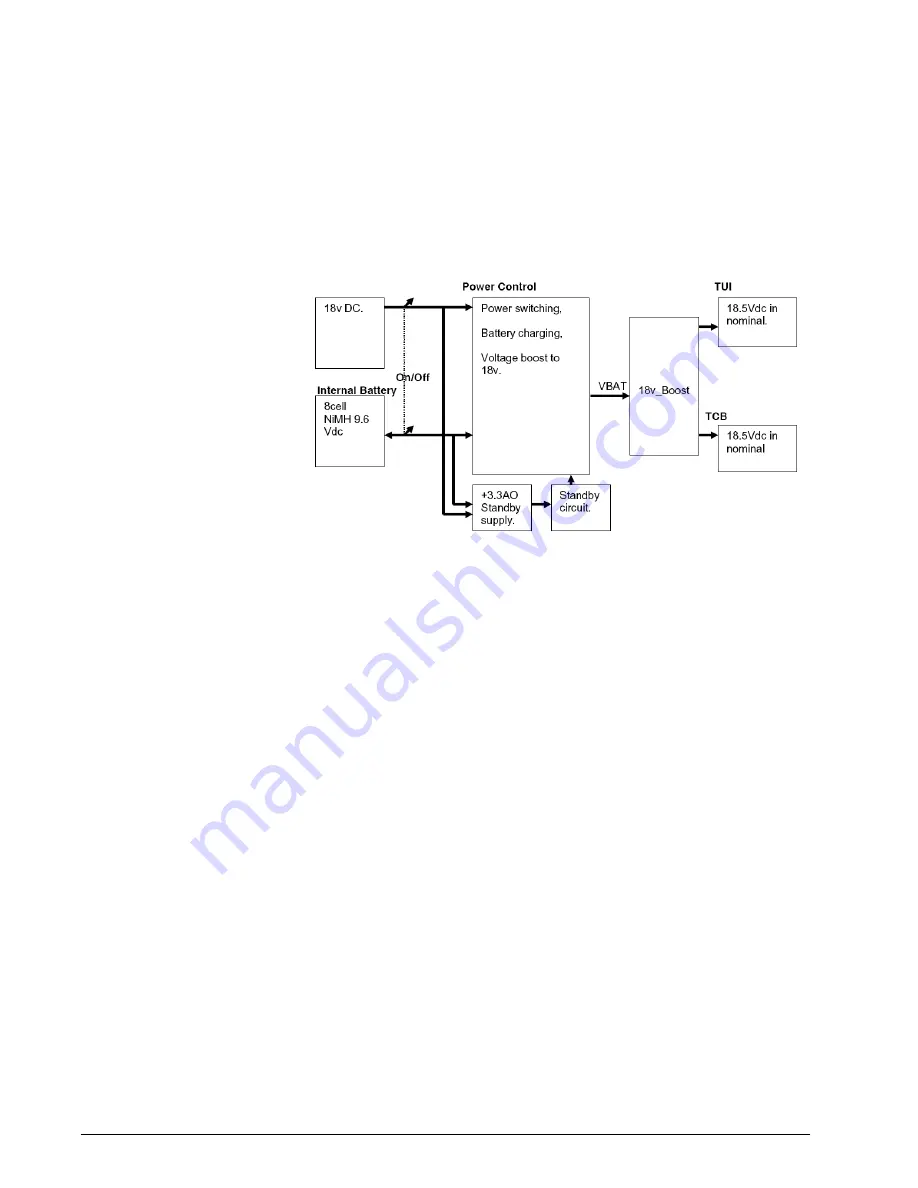

This section shows power (Figure 8-19) and communication (Figure 8-20)

interconnections.

Figure 8-19: Power Interconnection

External AC/DC power supply