en

4

2

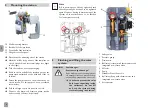

Mounting the station

10

11

12

13

10 Wall mounting bracket

11 Back half of the insulation

12 Front half of the insulation

13 Hinged controller panel

Î

Determine the mounting site of the station.

Î

Mark the drill holes by means of the template en-

closed, then drill and insert wall plugs (see fi gure

to the right).

Î

Take the station out of the packaging.

Î

Remove the front half of the insulation. Leave the

pump station attached to the back half of the in-

sulation!

Î

Fasten the pump station to the wall with the en-

closed screws. For this purpose, use a crosshead

screw driver.

Î

Fold the hinged controller panel to the left.

Î

Connect the pipework between pump station

and store and collector respectively.

Note

All connections are already tightened such

that they usually do not have to be tightened

again. However, during commissioning of the

system all connections have to be checked

for leaks (pressure test).

3

Flushing and fi lling the solar

system

WARNING!

Scald danger!

Pressure surge damage!

If the medium enters strongly heat-

ed, empty collectors, pressure surg-

es caused by evaporation can occur.

Î

In order to prevent the solar

fl uid from vaporising inside

the collectors, do not fi ll

or fl ush the system during

times of strong irradiation!

1 Safety valve

2 Pressure gauge

3 Drain valve

4 Ball valve (return) with thermometer and

integrated non-return valve

5 Fill valve

6 Pump

7 Grundfos Direct Sensor

TM

8 Ball valve (fl ow) with thermometer and

integrated non-return valve

9 Air separator

5

4

3

1

2

6

7

9

8