Important :

Read this manual and all labels carefully before operating your powder actuated tool.

This manual should always accompany the tool and be transferred with it upon change

of ownership.

REMINGTON

®

Operating

Instructions

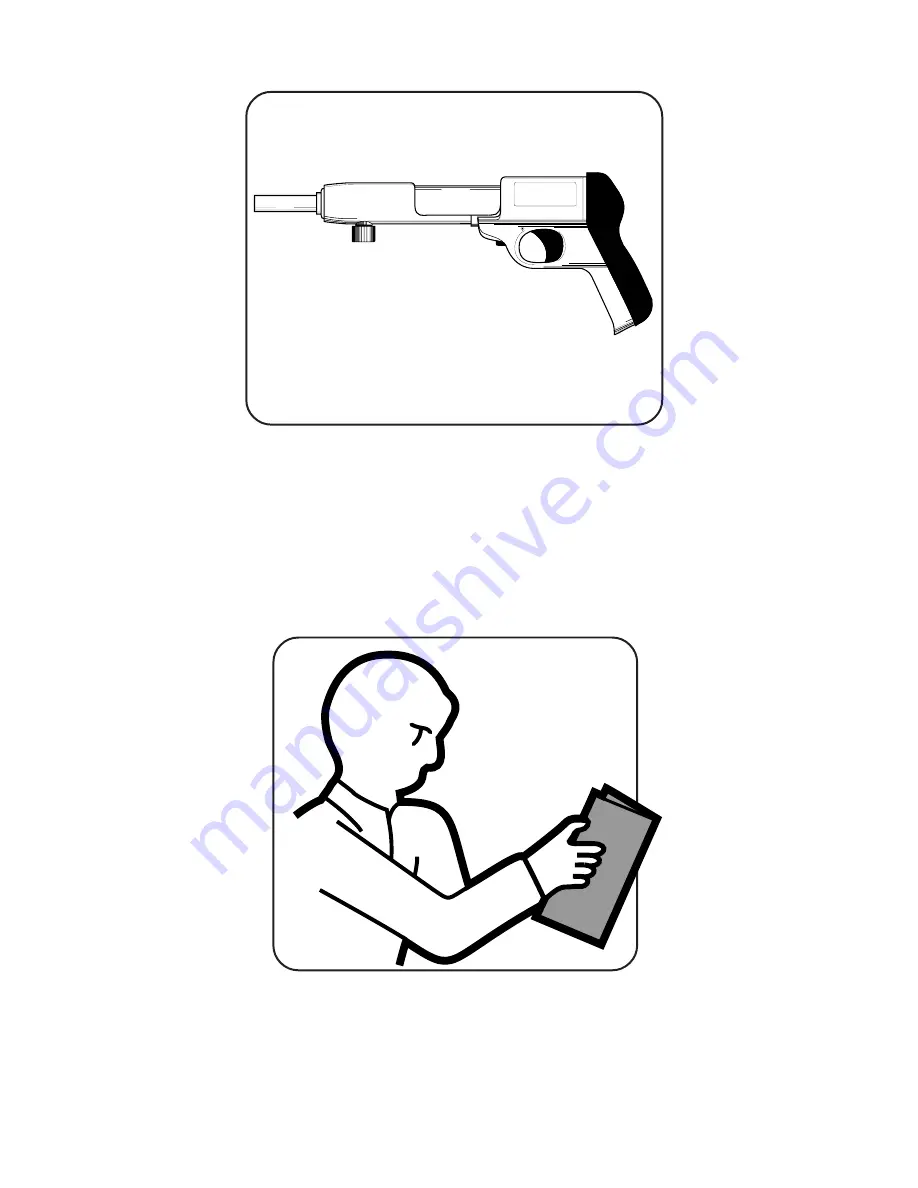

Model 482

Powder Actuated

Fastening Tool

REMINGTON