9

Alternatively the pipe thermostat (A) can be wired in

parallel with another pipe thermostat (b) which is

wired in series with a timeclock and room thermostat.

In this instance priority can be given to hot water by

setting the pipe thermostat (A) to approx. 85

o

C used

only to prevent boiling, the pipe thermostat (B) should

be set to approx. 55

o

C.

AT LEAST ONE RADIATOR (USUALLY THE BATH-

ROOM) SHOULD

NOT

BE FITTED WITH A TRV

(THERMOSTATIC RADIATOR VALVE), TO ACT AS

A HEAT LEAK, SHOULD THE BOILER OVERHEAT

AND THE PUMP FAIL TO START.

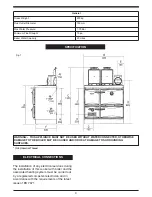

Fig.7

HIGH UPDRAUGHTS

Tall chimneys may develop excessively high up-

draughts which prevent the appliance operating cor-

rectly.

It is recommended that a proprietary brand adjustable

flue draught stabiliser having an openable cross sec-

tional area of 182.5sq cm (6”ø pipe) be fitted above

the flue pipe connection, either in the brickwork or into

a right angle ‘T’; fitting in the flue pipe position that will

not inconvenience appliance operation or mainte-

nance.

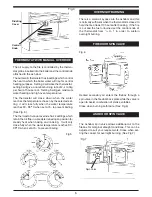

COOKER CLEARANCE

The Cooker should not be installed at zero clearance

to combustible materials. The sides should have a

minimum clearance of at least 75 mm (3”) from com-

bustible materials unless otherwise fully insulated.

This cooker is supplied with a back filler piece which

should be used with fitting the cooker between

kitchen units. This filler piece is mounted to the wall

behind the cooker using the appropriate screws and

rawl plugs (not supplied) and allows adequate clear-

ance from the front of the cooker to the front of the

kitchen units for door opening (see Fig.8 & 8a)

Fig.8

Fig.8a

Gap between Cooker & Kitchen units

must be filled using a filler strip

Cooker front must be

kept in line with front

of kitchen unit.

Back filler piece

Worktop

Worktop

75

75

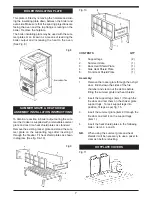

TESTING & COMMISSIONING

After completing the installation, the heating contrac-

tor should demonstrate to the user the operation of

the appliance and the routine cleaning method.

The protective grease should be removed from the

hotplate before lighting.

Check that the system is full of water and free from

air locks.

For the first couple of days do not overfire. The cast

iron inside the cooker will build up heat gradually and

overfiring may cause damage.

NOTE: SMOKE/SMELL EMITTED DURING INITIAL

USAGE

Some parts of the cooker have been coated with a

light covering of protective oil. During initial operation

of the cooker, this may cause smoke/smell to be emit-

ted and is normal and not a fault with the appliance,

it is therefore advisable to open doors and or windows

to allow for ventilation. Lift the lids to prevent staining

the linings.

Ensure all parts are fitted in accordance with the in-

structions.

On completion of the installation allow a suitable pe-

riod of time for any fire cement and mortar to dry out,

before lighting the stove. Once the stove is under fire

Summary of Contents for 370 SFW

Page 11: ...11 EXPLODED VIEW ...

Page 13: ...13 NOTES ...

Page 14: ...NOTES 14 ...

Page 15: ...15 NOTES ...

Page 29: ...13 NOTES ...

Page 30: ...14 NOTES ...

Page 31: ...15 NOTES ...