Scalar i6000 Installation Guide

47

3

Push the loose middle X-axis rail in the expansion module towards the X-axis rail in the control module

or expansion module to verify that there is no gap in the junction between the two rails.

4

While holding the X-axis rail against the adjoining rail use an 8 mm nut driver or open end wrench to

tighten the five 8 mm nuts on the X-axis rail alignment tool. This will align the two separate rails.

5

Working from left to right, tighten the ten 3 mm screws on the middle X-axis rail.

6

Use an 8 mm nut driver or open end wrench to loosen the five 8 mm nuts on the X-axis rail alignment

tool. Remove the tool from the X-axis rail.

7

Manually move the accessor over the rail junction points to verify that you cannot feel the junction.

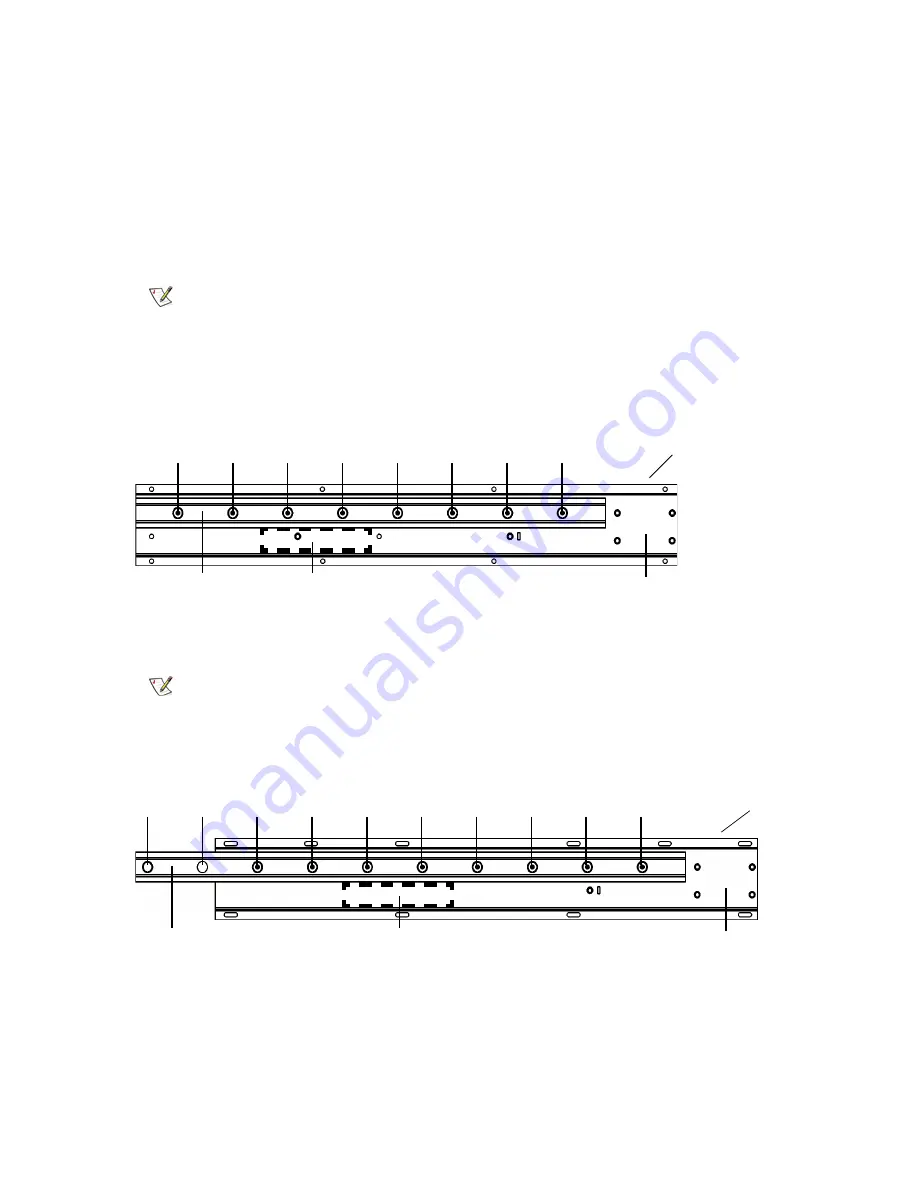

Verifying the Middle X-Axis Rail Alignment

1

Place the digital level on the lower side of the control module X-axis rail between screws 3 and 4 as

counted from the left. Record this value.

2

Place the level against the lower side of the expansion module X-axis rail between screws 5 and 6 as

counted from the left.

3

Verify that value for the expansion module middle X-axis rail is /- 0.05 degrees of the value

recorded for the control module. Make note of this value.

4

If the rail is not within this tolerance, align it as follows:

Note

There may be a slight clunk sound as you pass over the junction, but you

should not feel the transition between the rails in the accessor.

Note

Do not place the level on the control module X-axis rail alignment pins.

middle

X-axis

X-axis rail

channel

1

2

3

4

5

6

7

8

level

location

Control Module Rail

middle

X-axis

X-axis rail

channel

1

2

3

4

5

6

7

8

9

10

level

location

Expansion Module Rail

Summary of Contents for Scalar i6000

Page 20: ...8 About This Guide and Your Product...

Page 38: ...26 Installing a Stand Alone Control Module...

Page 104: ...92 Installing a Multi Module Library...

Page 156: ...144 Installing Cartridges...

Page 164: ...152 Setting up Your Library for Access...

Page 242: ...230 Configuring the Library...

Page 304: ...292 Adding Optional Hardware eight 2 5 mm screws...

Page 318: ...306 Adding Optional Hardware...

Page 336: ...324 Installation Testing and Verification Figure 35 Example Test Log Output...

Page 356: ...344 Testing and Calibrating the Digital Level...

Page 362: ...350 LBX Board and Terminator...

Page 380: ...368 Glossary...

Page 384: ...372 Index...