OPERATING INSTRUCTIONS (cont.)

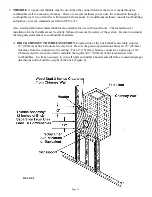

BLOWER OPERATING INSTRUCTIONS

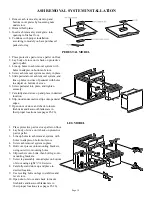

(see blower installation instructions on page 27)

If your Quadra-Fire wood stove is equipped with an optional blower, you should follow these guidelines:

1.

Initial (cold) start-up: Leave blower off until your stove is hot and a good coalbed is established. The blower may

be turned on approximately 30 minutes after loading the stove with fuel.

2.

High burn setting: The blower may be left on throughout the burn.

3.

Medium burn setting: The blower should be left off until a good burn is established, then turned on at a medium or

high rate.

4.

Low burn setting: The blower tends to cool off the stove. If you are using wet wood or a very low burn setting,

leave blower off until the burn is well established. Then, if you wish, turn the blower on at a lower rate. Too high a

blower setting with a low burn rate may adversely affect emissions.

5.

The blower is equipped with a speed control. The highest blower speed is obtained by turning the speed control on

and then adjusting back towards off as far as possible without turning the blower off. For a low blower speed, turn

the control knob clockwise as far as possible.

OPERATING TIPS

Here are a few tips on operating your Quadra-Fire stove to obtain maximum efficiency with lowest emissions:

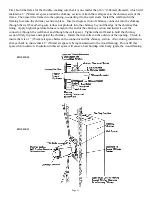

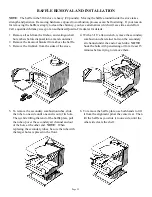

1.

Regardless of desired heat output, when loading stove, burn your Quadra-Fire with both air controls wide open for a

minimum of 15 minutes.

2.

Regulate burn rate (heat output) by using the secondary control (center, under ashcatcher). The primary control (on

the right) is mainly for initial start-up, reloading, or high burns.

3.

Heat output settings: Following 15 minutes of burning with controls wide open (see #1 above):

BTU/Hr.

Primary

Secondary

Below 10,000

Closed after 5 minutes

Pull to stop

10,000-15,000

Closed after 5 minutes

¾” - 1” open

15,000-30,000

Closed after 5 minutes

1” - 2½” open

Maximum heat

Full open

Full open

These are approximate settings, and will vary with type of wood or chimney draft.

4. Burn dry, well-seasoned wood (see section on wood selection and storage, page 22).

BURNING GUIDELINES

Aladdin Hearth Products, is deeply concerned with the air quality in your community. In order to maintain clean air, it is

very important to burn your wood stove in the most efficient manner possible. Following these guidelines will insure

environment-friendly operation.

OPACITY

This is the measure of how cleanly your stove is burning. Opacity is measured in percent; 100% opacity is when an

object is totally obscured by the smoke column from a chimney, and 0% opacity means that no smoke column can be

seen. As you become familiar with your stove, you should periodically check the opacity. This will allow you to know

how to burn your stove as nearly smoke-free as possible (goal of 0% opacity).

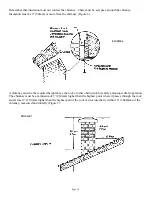

WOOD

Burn only dry seasoned wood. Store wood under cover, out of the rain and snow.

BURN RATES

HIGH:

Open (push in) both controls fully. It is important to do this when reloading the stove. Failure to do this could

result in excessive emissions (opacity).

Page 21

Summary of Contents for 3100 Series

Page 30: ...NOTES Page 30...

Page 31: ...NOTES Page 31...