$ERXWWKH

)ROGHU6WDSOHU

8VLQJWKH4'2&6\VWHP

&RQWURO3DQHO.H\V

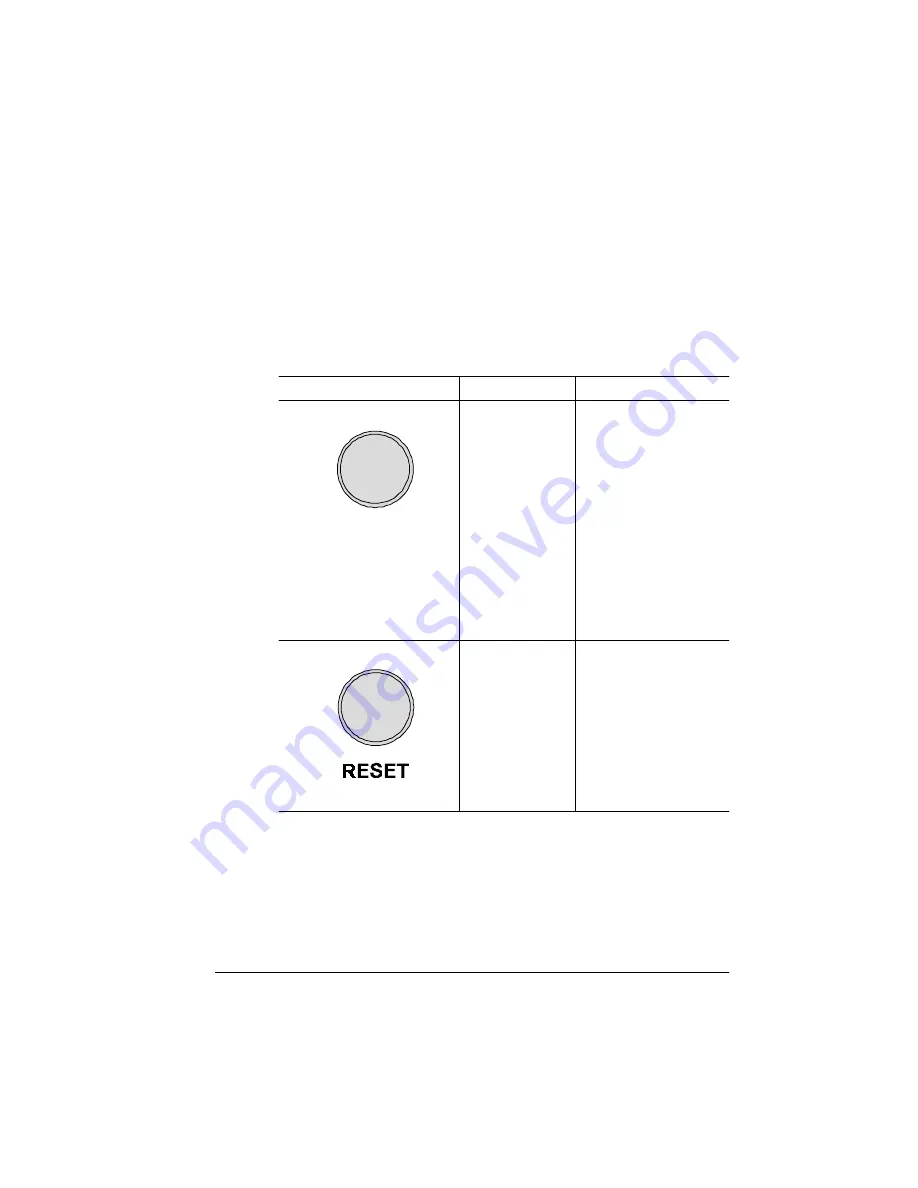

The following control panel keys access Folder/Stapler options.

»

Note:

The Reset and Test keys may be used only when the Folder/

Stapler is off line. If they are activated while the Folder/Stapler is on

line, they have no effect.

Symbol

Name

Function

Online

The OnLine key

toggles the Folder/

Stapler from on line

to off line status.

When the unit is on

line, the green

ONLINE light is on.

» Note:

In the off line

position, the Folder/

Stapler cannot

receive any signals

from the

QMS 4060.

Reset

The Reset key sets

the Folder/Stapler to

its default state.

When an error

occurs, press the

Reset key to clear the

error and place the

Folder/Stapler back

on line.

ONLINE

Summary of Contents for QDOC

Page 1: ...k k 3 k bk p p...

Page 9: ...QWURGXFWLRQ Q 7KLV KDSWHU Introduction on page 1 2 Standard Product Documentation on page 1 5...

Page 32: ......

Page 46: ......

Page 122: ......

Page 140: ......

Page 141: ...2SWLRQV Q 7KLV KDSWHU Introduction on page 7 2 Stapler Head on page 7 2...

Page 143: ...6WDSOHU HDG 2SWLRQV 3 Open the cover RYHU...

Page 154: ......

Page 172: ......