B

& ( "

'''

"

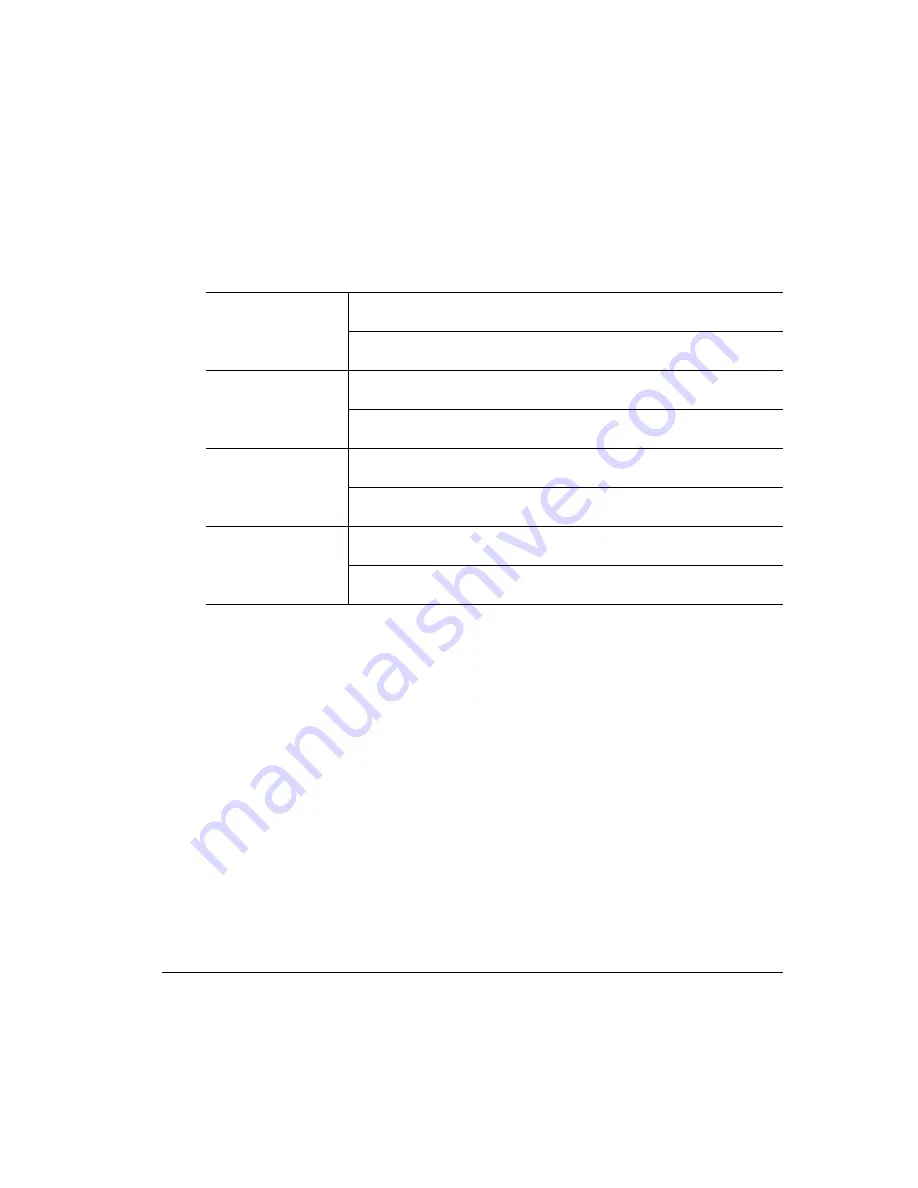

This hotlink provides the status on established timeouts.

Wait

Shows the maximum number of seconds the PostScript emulation waits

for incoming data before ending the job.

Configuration Menu: Administration/Communications/Timeouts/PS

Wait Timeout

Job

This shows the maximum number of seconds the printer processes a

PostScript job before it ends the job.

Configuration Menu: Administration/Communications/Timeouts/Job

Timeout

Emulation

Shows the maximum number of seconds emulations other than

PostScript wait for incoming data.

Configuration Menu: Administration/Communications/Timeouts/

Emulation Timeout

ESP

Shows the maximum amount of time ESP will wait to get a minimum

amount of data before selecting an emulation.

Configuration Menu: Administration/Communications/Timeouts/ESP

Timeout

Summary of Contents for Magicolor 6100

Page 1: ......

Page 10: ......

Page 18: ...6 7 8...

Page 24: ......

Page 206: ......

Page 207: ...0 1 1 1 Sources of Support on page A 2 QMS World wide Offices on page A 4...