9

The equipment full of water weighs more, the distribu-

tion of weights in an uneven position could cause some

connection element to be forced, thus generating a

malfunction, damage to equipment components or loss

of water.

• The place intended for its installation must have suffi-

cient space for the apparatus itself, its accesses, con-

nections and for the realization of a comfortable main-

tenance (3).

• Under no circumstances should the equipment be ins-

talled outdoors (4).

• The environment and environment where equipment

and tap are installed must comply to adequate hygie-

nic-sanitary conditions.

· The appliance is only to be used with the power supply

unit provided with the appliance.

· This appliance must only be supplied at safety extra low

voltage.

• Avoid external drips on the equipment, coming from

pipes, drains, etc.

ATTENTION: Equipment must not be installed next to

a heat source or directly receiving a flow of hot air

on it (dryer, refrigerator, etc.).

· The new hose-sets supplied with the appliance are to

be used and that old hose-sets should not be reused.

3.1. COMMISSIONING AND MAINTENANCE

ATTENTION: Water treatment equipment needs

periodic maintenance by qualified technical per-

sonnel, in order to guarantee the quality of water pro-

duced and supplied.

· Consumable elements must be replaced with the fre-

quency indicated by the manufacturer.

• The equipment must be sanitized periodically and

prior to its commissioning.

• After putting into service, it must discard the water

produced during the first 30 minutes of use.

• Maintenance must be carried out by qualified tech-

nical personnel, with appropriate attitude and hygienic

conditions, in order to reduce the risk of internal con-

tamination of the apparatus and its hydraulic system.

(For more information contact the technical service of

your distributor).

4. UNPACKING

It is important that before installation and commissio-

ning, check the box and condition of the equipment,

in order to ensure that they have not been damaged

during transport.

ATTENTION: Claims for damage during transport

must be submitted together with the delivery note

or invoice to your distributor, attaching the name of

• It is recommended that the water to be treated be de-

calcified or with a maximum hardness of 15 ºHF in order

to obtain an optimal performance of the equipment.

• In the event that the water to be treated is of a hard-

ness greater than 15 ºHF, there could be a reduction in

the life of the membrane and in the performance of the

equipment.

• In the event that the input water contains a concen-

tration greater than 1.2 ppm of the total chlorine, the

installation of an activated carbon filter is recommen-

ded to reduce the concentration of chlorine in the wa-

ter and thus protect and extend the life of the compo-

nents of the equipment.

In case the water to be treated contains:

High concentrations of iron and manganese (Greater

than 1ppm measured in machine rejection).

Prolonged hyper chlorination over time.

Sludge or turbidity greater than 3 NTUs.

A nitrate concentration greater than 100 ppm.

A sulfate concentration greater than 250 ppm.

• Contact your dealer to recommend the most appro-

priate pretreatment for you, to ensure the correct ope-

ration of the equipment, avoid damage to components

and guarantee the quality of the water supply.

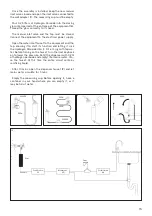

3. INSTALLATION OF THE EQUIPMENT

• In case of having to condition the installation of the

house to be able to install the equipment in the fore-

seen place, it must be carried out following the national

standards for interior installations of water and electri-

cal supplies.

• This equipment needs an electrical outlet less than 1

meter away (1).

• This equipment should not be installed lying down or

tilting (2), because the leak sensor will be disabled.

1

1 m

3

2

4

Summary of Contents for VYRTA direct flow

Page 1: ...1 USER MANUAL EQUIPMENT REVERSE OSMOSIS ...

Page 2: ......

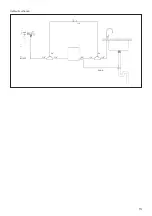

Page 13: ...13 IN FEED DRAIN 3 8 1 4 RO 3 8 1 4 1 4 1 4 1 4 Hydraulic scheme ...

Page 17: ...17 ...

Page 28: ...NOTES ...

Page 29: ...NOTES ...

Page 30: ...NOTES ...

Page 31: ...NOTES ...