PG1202S MANUAL

Power Management

• Start engine without anything connected to generator.

• When engine has stabilized, plug in and turn on first load. It is strongly recommended to plug in devices with the largest

output first and the smallest output last to help prevent overloading the generator.

• Allow generator output to stabilize (engine and attached devices run evenly) before plugging in the next load.

Cold Weather Operation

Under humid conditions where temperatures drop to 40ºF (4ºC) the carburetor and/or crankcase breather system may begin

to freeze. To prevent icing take the following steps:

1. Replace any old fuel with clean, fresh fuel.

2. Turn fuel valve to the open position.

3. Ensure generator is serviced according to the maintenance schedule under “Maintenance” section of manual.

4. Shelter unit from elements.

WARNING!

Never exceed generator’s wattage / amperage capacity. This could damage the generator

and / or connected electrical devices.

Check operating voltage and frequency requirements of all electrical devices prior to plugging them into the generator.

Summary of Contents for PG1202S

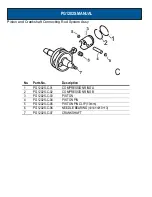

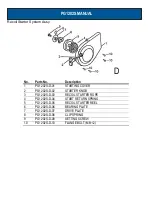

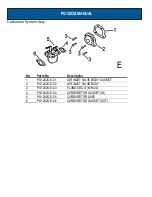

Page 24: ...PG1202S MANUAL PARTS LIST...