19

S-PARK

- rev.1.1_06_2020

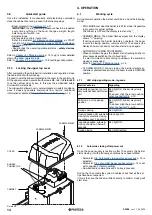

5.3.7

U. Maintenance

U.1 Overall cycles performed

This feature allows to display the overall cycles performed.

No possibility of reset.

Cycles are displayed 2 by 2 figures:

Ex.:

if the barrier totally performed 823.605 cycles, the screen will

read:

00. 82 36 0.5.

If you wish to scroll figures just press key

.

U.2 Cycles performed since last maintenance service

This feature allows to display the overall cycles performed since last

maintenance service.

Cycles can be reset when a maintenance service has been carried

out (if U.3 is updated and set up).

If you wish to reset press and together holding for 3 seconds:

display will flash “

” to confirm reset successfully completed

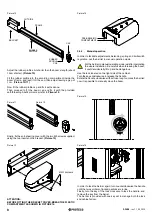

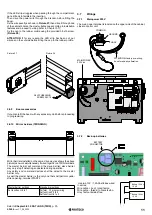

P.4 LED signalling strip (optional)

Boom can be fitted with a RGB led strip that makes the operation more

visible.

The LED strip can be adjusted in 4 different signalling modes when

boom is in closing position.

Refer to be below table:

P.4

Signalling mode when boom in closing position

0

OFF

1

Lit (red light); flashing if battery powered

2 (default) Lit (red light).

3

Flashing (red light)

P.5 Light sensor

It is possible to wire a light sensor or daily/weekly timer to switch

the LED signalling strip OFF during day hours.

There are two possible configurations:

• Wiring the N.O. contacts of the sensor/timer in series to COMMON

(terminal BOOM+24)

• Wiring the N.O. contacts of the sensor/timer between GND

and STRT2 or LD, setting

P.5

accordingly; in this case the wired

terminal looses its original function.

P.5

Light sensor possible configurations

0 (default)

No light sensor is wired to STRT2 or LD.

1

Light sensor is wired between STRT2 and COM.

START2 no longer works as pedestrian contact.

2

Light sensor is wired between LD and GND.

LD no longer works as Loop detector.

P.6 Cabinet’s safety switch

The barrier may develop extremely dangerous circumstances during

operation.

That’s why if cabinet is opened the barrier immediately stops working

(just figure out if accidentally a radio start command is given, how

dangerous it could be).

However barrier can be managed in “dead man” mode using on

board keys.

P.6

safety function may be switched OFF setting

P.6

to 0 position; by

default

P.6

is

ON (P.6=1)

.

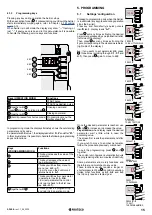

U.3 Maintenance countdown

This feature allows to set the number of cycles till next maintenance

service (starting from a minimum of 1000 cycles and so on).

U.3

will accordingly and automatically update

U.1

and

U.2

if activated,

at every closing operation.

It is also possible to warn the end user that maintenance service is

needed.

To set this function, set parameter

U.4

.

U.4 Maintenance recall

As previously explained in parameter

U.3

, it is possible to set a

visible flashing “maintenance recall”.

Refer to the below table to set the desired recall configuration:

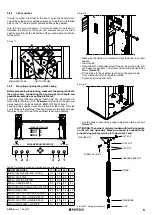

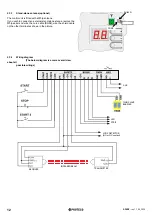

P.3

LD output / features and contacts (N.O./N.C.)

0 (default)

The contact is OFF.

1

N.O. (normally opened) START command.

The closed contact makes the barrier opening.

2

N.O. SAFETY mode

The closed contact makes the barrier reverting exactly

as a closing photocell.

3

N.C. (normally closed) START command

See setting 1 above.

4

N.C. (normally closed) SAFETY mode

See setting 2 above

U.4

Maintenance recall – signalling configuration

0

(default)

OFF – factory setting

No maintenance recall has been activated.

1

SPECIAL FLASHING DURING AUTOMATIC CLOSING TIME

When boom in vertical position, the flashing light on the cabinet

permanently flashes.

To activate this mode the automatic closing time shall be set

no less than a couple of seconds, otherwise signalling will not

be sufficiently visible

.

2

SPECIAL FLASHING DURING OPENING

When boom is opening, the flashing light on the cabinet

permanently flashes.

3

AUX OUTPUT

AUX output activates (the contact closes) when maintenance

service is neeed.

P.3 LD loop detector

P.3 allows to fit to LD terminal a vehicle detector (loop detector) that

works exactly as a safety device, like closing photocell.

In addition it can command a START pulse: when the vehicle

approaches the barrier, a START command is given and the barrier

opens.

Settings available: