5.11

oil with skin wash the place of contact with water and soap. Do not apply organic solvents

(petrol, kerosene). Contaminated clothing should be changed to prevent access of oil to skin.

In the event of contact of oil with eye, rinse with large quantity of water and in the event of the

occurrence of irritation consultant a doctor. Hydraulic oil in normal conditions is not harmful to

the respiratory tract. A hazard only occurs when oil is strongly atomised (oil vapour), or in the

case of fire during which toxic compounds may be released. Oil fires should be quenched

with the use of carbon dioxide, foam or extinguisher steam.

5.6

LUBRICATION

Trailer lubrication must be carried out in places indicated in figures (5.6A) & (5.7A), and also

detailed in table (5.4).

TABLE 5.4

GREASING POINTS

ITE

M

NAME

NUMBER OF

GREASING

POINTS

TYPE OF

GREASE

GREASING

FREQUENCY

1

Articulated joints and

sockets for installation of

load box.

4

permanent

2 months

2

Sockets for installation of

tipping ram cylinder

2

permanent

6 months

3

Absorber spring pins

4

permanent

6 months

4

Rocker arm pins

2

permanent

6 months

5

Absorber spring sliding

surfaces

4

permanent

1 month

6

Axle bearings

4

permanent

24 months

7

Axle expander shaft

sleeves

4

permanent

6 months

8

Absorber spring

4

anticorrosion

and penetration

6 months

9

Wall extension hinges and

wall locks

10

permanent

1 month

10

Handbrake mechanism

1

permanent

6 months

Summary of Contents for T780

Page 2: ......

Page 5: ......

Page 17: ...1 10 ...

Page 43: ...3 14 ...

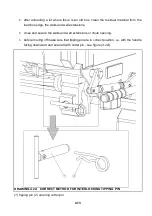

Page 72: ...5 13 DRAWING 5 6A CHASSIS GREASING POINTS ...

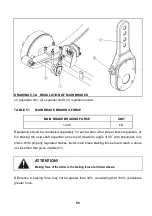

Page 73: ...5 14 DRAWING 5 7A LOAD BOX GREASING POINTS ...

Page 80: ...5 21 ...

Page 81: ...NOTES ...

Page 82: ... ...