Description

16 / 21

4.5.

Controls and adjustments

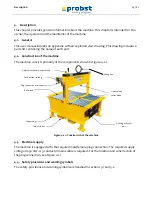

The machine has the following controls and adjustments as shown in Figure 4.2-1:

Handle for adjustment of the upper blade

Push button for cutting

4.6.

Operation

The natural stone blocks can be placed on the roller bed with the same orientation as on the

pallet.

By turning the handle on the top of the machine, the distance between the upper and lower

blades can be adjusted. The blades always remain parallel because the spindles on both sides of

the blades are connected by a chain drive.

The upper blade must be adjusted so there is 0 to 5 mm of free space above the stone.

As soon as the machine is connected to the mains supply, the hydraulic unit is in "stand-by".

During the cutting movement, the lower blade moves upward. The stroke is 25 mm.

The lower blade moves upward when the appropriate push button is pushed, see Figure 4.2-1.

When the push button is released again, the lower blade returns to its original position.

The upper and lower blades are made of hardened steel and each have 3 cutting edges. When a

cutting edge has become dull, the blade can be rotated. To see how the blades are attached,

see the exploded view drawing.

4.7.

Technical data

Type

AL-90/NSH-40

Serial number

The serial number is punched in the side plate.

See Figure 2.3-2

Maximum cutting presure

40,000 kg

Weight

500 kg

Minimum cutting width

b=400 mm

Maximum cutting width

b=900 mm

Range of cutting height

h = 40-370 mm

Pump

M319-03-230 V

Required supply voltage

220-230 VAC

Oil

Bio degradable hydraulic oil

Type: Castrol Carelube SES 32

Summary of Contents for AL-90

Page 3: ......

Page 29: ......

Page 30: ...51200054 V1 GB Opreration Instructions Hydraulic block cutter Typ AL 90 NSH 40 ...