6

Jack Stands

PREPARATION

1. Before using this product, read the owner’s manual and familiarize yourself thoroughly with the product and the

hazards associated with its improper use.

2. Inspect stands before each use. Do not use if bent, broken or cracked components are noted. Ensure that all

parts move freely.

3. Verify the product and your application are compatible. If in doubt, contact Pro-Lift Customer Support @ (816)

891-6390.

4. Install ratchet bar into frame. Ratchet portion of bar must be aligned with ratchet pawl (stopper).

5. Move the ratchet bar to its lowest position by raising the locking handle, releasing the ratchet pawl, and guiding

the bar downward.

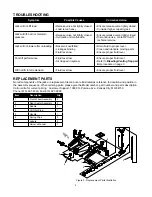

6. Ratchet bar/collar lock is accomplished by bending the press tab (Fig.1) inward using a suitable hammer and

punch. This will prevent inadvertent loss of the ratchet bar.

7. Always check the vehicle owners or service manual for location of proper lift and support points.

• Study, understand, and follow all instructions

before operating the device.

• Do not exceed rated capacity.

• Use only on hard, level surface.

• Center load on saddle.

• Use as a matched pair only.

• Stands are not to be used to simultaneously

support both ends of a vehicle.

• No alterations shall be made to this product.

• Failure to heed these markings may result in

personal injury and/or property damage.

!

WARNING

!

WARNING

To avoid crushing and related injuries:

NEVER work on, under or around a

load supported only by a hydraulic jack.

ALWAYS use adequately rated jack

stands.

OPERATION

Supporting a load

WARNING:

Use only on areas of the vehicle specified

by the vehicle manufacturer. Use only on vehicles

whose support points are compatible with the saddle

of these jack stands. Incompatibility may result in

structural damage to the vehicle and/or jack stand.

Structural damage to either may result in sudden and

unexpected loss of load height.

1. Adjust height by pulling up on ratchet bar.

2. Locking handle weight should secure the ratchet bar in desired position. To confirm this, push down on the locking

handle. Ensure locking handle and ratchet bar are secure before loading.

3.

Carefully

position jack stands so that load is centered on saddle.

4.

Slowly

lower the vehicle onto the stands.

5. Ensure vehicle is secure before working on, around or under. Use wheel chocks on all unlifted wheels in both

directions to prevent inadvertent movement.

Lowering load

WARNING:

Clear all tools and personnel before lowering load.

1. Using suitable jack, raise vehicle clear of stands.

2. Release locking handle and adjust ratchet bar to lowest position.

3. Remove stands, then lower vehicle.

MAINTENANCE

Periodically inspect both stands. Ensure all parts move freely. Do not apply oil or grease to any portion of this prod-

uct. If rust appears, sand affected area and cover with suitable utility paint. Please note that there are no replace-

ment parts applicable to this equipment. Replacement stands must be purchased as a matched pair.

Storage

Store stands in upright position and in a clean, dry area.

!

!