20 -

PRM 60

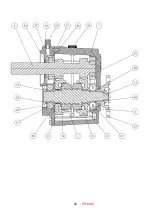

12.PARTS LIST

ITEM NO.

PART No

DESCRIPTION

QTY.

1

MT8600

FRONT COVER

1

2

MT8601

GEARCASE

1

3

MT8606-H MT8604-H MT8608-H

INPUT SHAFT (1.52:1), (2:1), (2.5:1)

60D MODELS

1

3

MT8691-H MT8692-H MT8693-H SHORT INPUT SHAFT (1.52:1), (2:1), (2.5:1)

60DS MODELS ONLY

1

4

0562006

NEEDLE BEARING

2

5

MT8675

THRUST WASHER

1

6

MT8602-H

IDLER GEAR

1

7

MT8611

IDLER SHAFT

1

8

0592503

THRUST WASHER

2

9

0593003

THRUST WASHER

2

10

MT8677 MT8678 MT8679

OUTPUT WHEEL, FORWARD (1.52:1), (2:1), (2.5:1)

1

11

MT8688

CONE CLUTCH

1

12

MT8680

OUTPUT WHEEL, REVERSE

1

13

010N251

LOCKNUT

1

14

MT8610

OUTPUT SHAFT

1

15

0311042

SELECTOR SPRING

1

16

010-0210

SPRING DOWEL

1

17

MT8104

SELECTOR PIN

1

18

MT8616

SELECTOR BODY

1

19

MT8615

SELECTOR HOUSING

1

20

04303524

O' RING

1

21

0400255

OIL SEAL

1

22

MT8103

SELECTOR SHOE

1

23

MT8670

OUTPUT COUPLING

1

24

0400286

OIL SEAL

1

25

MT8674

BINX NUT

1

26

0150125

¼” BSP LEVEL

PLUG

1

27

0210614

DOWEL PIN

2

28

0970147

3/8” BSP FILLER/

DIPSTICK

1

29

N/A

SERIAL PLATE

1

30

CP1003

SERIAL PLATE PINS

2

31

AM161

BALL BEARING

2

32

0512030

BALL BEARING

1

33

010W252

LOCKWASHER

1

34

MT8118

NUT

1

35

0563005

NEEDLE BEARING

2

36

0513010

BALL BEARING

1

37

0191245

WAVED WASHER

1

38

0400356

OIL SEAL

1

39

06905206

SHAMBAN END COVER

1

40

0081420P

CAP SCREW

2

41

CP1486

RED LABEL

1

42

MT8676

SELECTOR LEVER

1

43

0040809ZP

SET SCREW

1

44

0191007MZP

WASHER

1

45

04908025ZP

STUD M8 X 1.25

2

46

CP1489

¼

”

BSP MAGNETIC DRAIN PLUG

1

47

0050810

NUT

1

48**

014D525

DOG POINT GRUB SCREW

1

49

04908025ZP

STUD

2

50

04301416

IDLER SHAFT 'O' RING

1

51

CP1204

BONDED WASHER

BONDED SEAL

2

52

0040607ZP

BOLT

10

53

CP1488

BR

EATHER VALVE 1/8” BSP

1

54

CP1224

SEALING WASHER 1/8” BSP

1

55

CP1223

SEALING WASHER 5/16”

1

** USE LOCTITE THREAD SEALANT 542 ON THREAD

Summary of Contents for PRM 60

Page 1: ...PRM 60 WORKSHOP MANUAL...

Page 2: ......

Page 11: ...9 PRM 60 BASIC INSTALLATION DETAILS PRM 60 Figure 4 Intallation Details...

Page 23: ...21 PRM 60 13 Exploded view and Cross section Figure 5 Exploded view and cross section...

Page 24: ...22 PRM 60...

Page 25: ...23 PRM 60...

Page 26: ...24 PRM 60...

Page 28: ...26 PRM 60 NOTES...