Chapter 5

General Operation Factors

35

Note:

Do not be concerned about either the DC level of this background noise or its

shape unless it is very high, i.e., > 1000 counts with 16-bit A/D. What you see is not

noise. It is a fully subtractable readout pattern. Refer to

,

page 38, for more information.

If you observe a sudden change in the baseline signal you may have excessive humidity

in the camera's CCD enclosure.

Immediately

turn off the controller.

Then, contact

Princeton Instruments Customer Support for further instructions. See page 146 for

contact information

.

Clean Cycles

As stated before, dark charge integrates on the array whenever the camera is on, whether or

not data acquisition is occurring. To minimize the dark charge and other noise in the pixel

wells when data acquisition is idle, the Clean Cycles function shifts accumulated charge in a

predefined number of rows to the shift register and then discards it.

Clean cycles start when you turn on the camera and a clean pattern is programmed into it. At

the end of a cycle, the camera checks to see if a Start Acquisition command has been

received. If it has been received, the user-defined number of cleans (typically 0) will be

then performed before the exposure starts. If a Start Acquisition has not been received, the

next clean cycle begins.

The number of rows that are shifted and discarded during a clean cycle are defined in the

application software (for example, on the WinView/WinSpec

Setup|Hardware|Cleans/

Skips

tab page). The most effective cleaning occurs when the number of rows equals the

number of rows on the CCD. However, you need to keep in mind that a clean cycle must be

completed before a Start Acquisition command will be implemented. The more rows in a

cycle, the greater the delay between the command receipt and the beginning of an exposure.

Because of this timing issue, the number of rows per clean cycle is usually much smaller than

the number of rows on the array.

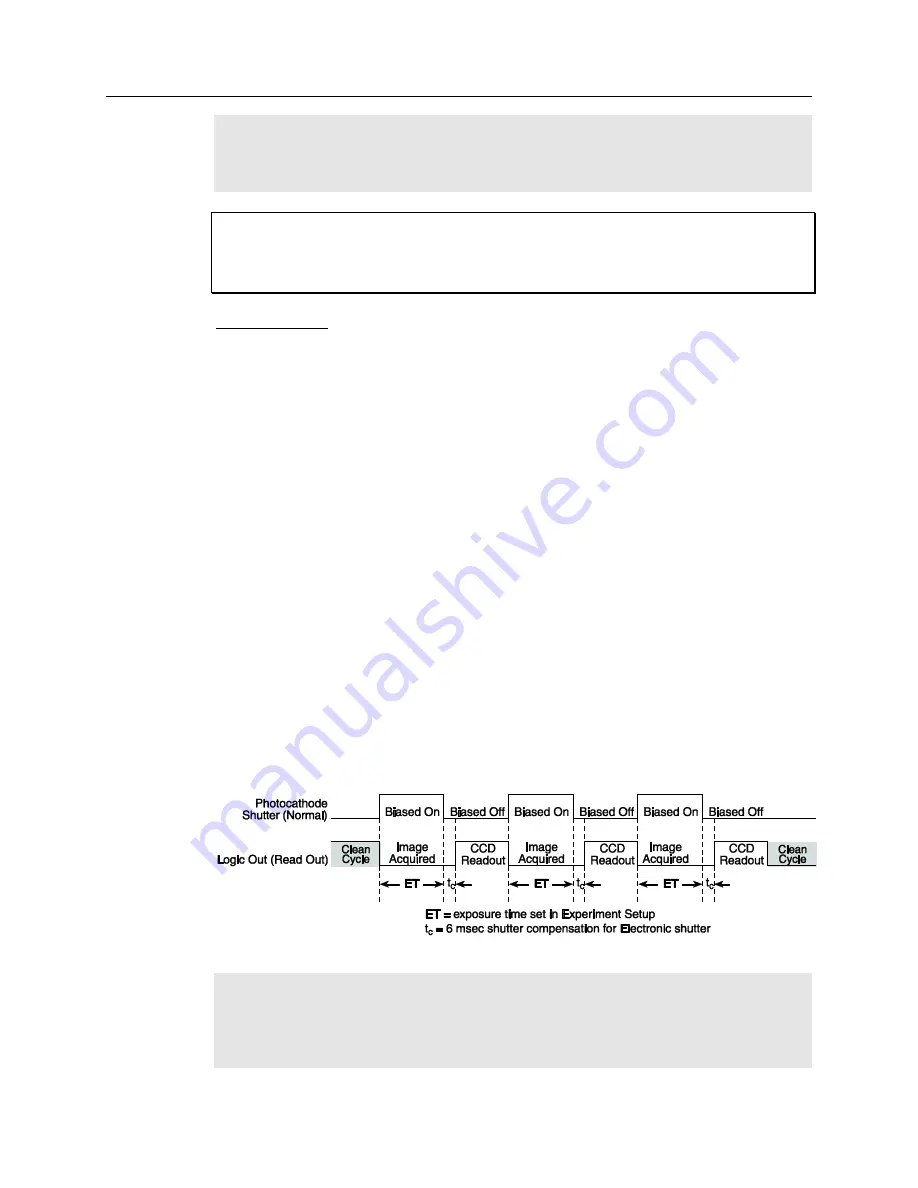

The timing diagram below is for an experiment set up to acquire three (3) images using

Internal trigger mode (selected on

SuperSYNCHRO Trigger In

tab page) and Gate Mode

(selected on

Experiment Setup Main

tab page). In this diagram, clean cycles occur before

the first exposure and after the last readout period. They do not need to occur between

exposures since each readout cleans the array before the next exposure starts.

Figure 7. Clean Cycles in Internal Trigger Mode of Operation

Note:

The start of the exposure is signaled by the

Read Out

output of the

LOGIC OUT

connector going low but will not occur until the current clean cycle and the additional

user-defined number of cleans (typically 0) have finished. "Number of Cleans" is defined

on the

Setup|Hardware|Cleans/Skips

tab page. If you enter a value other than "0", you

will further delay the start of the exposure by that number of clean cycles.

WARNING!

Summary of Contents for PI-MAX 3 System

Page 1: ...4411 0129 Version 1 A September 8 2010 4411 0069 ...

Page 32: ...32 PI MAX 3 System Manual Version 1 A This page intentionally left blank ...

Page 52: ...52 PI MAX 3 System Manual Version 1 A Figure 20 Safe Mode and Fast Mode Operation ...

Page 72: ...72 PI MAX 3 System Manual Version 1 A This page intentionally left blank ...

Page 90: ...90 PI MAX 3 System Manual Version 1 A This page intentionally left blank ...

Page 100: ...100 PI MAX 3 System Manual Version 1 A This page intentionally left blank ...

Page 110: ...110 PI MAX 3 System Manual Version 1 A Figure 68 Outline Drawing PI MAX3 with F mount Adapter ...

Page 114: ...114 PI MAX 3 System Manual Version 1 A This page intentionally left blank ...

Page 120: ...120 PI MAX 3 System Manual Version 1 A This page intentionally left blank ...

Page 140: ...140 PI MAX 3 System Manual Version 1 A This page intentionally left blank ...