PREBENA

Wilfried Bornemann GmbH & Co. KG

BEFESTIGUNGSTECHNIK

– FASTENING TECHNOLOGY

22

8.3.1 Checking the oil level

The oil level is visually

(Figure 6)

inspected. The maximum fill level is the lower edge

of the oil filler neck and the lower limit is located at the centre of the viewing window

(in the case of a cold compressor).

If oil colour changes occur (

whitening- contains

water, darkening - extreme overheating

), change the oil immediately

(point 8.3.3).

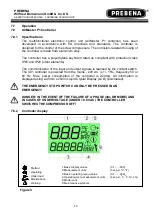

8.3.2

Recommended types of oil

The nominal lubricating oil capacity for the compressor can be found in the

"Spare

parts for maintenance"

table in

Appendix F

. It is recommended that your do not

mix the different varieties and mineral compositions of the oil. We advise using the

following oil brands and types for the compressor. However, similar or equivalent oil

brands or types can be used.

The screw compressor is shipped from the factory with

mineral oil.

Manufacturer

Type of oil

PREBENA

Z.200.70 Mineralöl

PREBENA

Z.200.80 Synthetiköl

WARNING: COMBINING DIFFERENT TYPES OF OIL AND OIL FROM

DIFFERENT MANUFACTURERS IS STRICTLY FORBIDDEN AND VOIDS THE

WARRANTY / GUARANTEE.

NOTE: SELECT A HIGH QUALITY OIL FOR SCREW COMPRESSORS, WITH A

VISCOSITY OF 46 MM2/S AT 40°С, FLOW POINT FROM -8 to 10°С, WITH AN

IGNITION TEMPERATURE OF MORE THAN 200 ° С.

When replacing the compressor oil, it is important to completely remove the oil from

oil reservoirs, screw conveyor unit, condenser and oil circulation lines. In addition, the

oil filter and oil separator must be replaced.

8.3.3 Oil Change

When changing the oil, it is necessary:

1 To remove the right cover of the compressor housing.

2 To switch the compressor on, so that the oil can heat to over 71

С (the radiator

is simultaneously heated over the entire surface).

3 To switch off the compressor.

4 Within 5 minutes, unscrew the plug and slowly open the drain valve to remove

the oil. Then all of the oil can be drained into a container and prepared for

disposal.

5 To manually turn the screw 3-5 revolutions in the direction of the arrow on the

front of the worm screw.

6 To remove the oil filter.

7 To install a new filter (before installing the filter, pour in a little oil so that the filter

element is impregnated and then lubricate the gasket of the filter with oil). To do

so, use the same oil as for filling the compressor.

8 To dismantle the filter / oil separator.

Summary of Contents for SK-15-10

Page 33: ...PREBENA Wilfried Bornemann GmbH Co KG BEFESTIGUNGSTECHNIK FASTENING TECHNOLOGY 33 ANHANG...

Page 35: ...PREBENA Wilfried Bornemann GmbH Co KG BEFESTIGUNGSTECHNIK FASTENING TECHNOLOGY 35...

Page 36: ...PREBENA Wilfried Bornemann GmbH Co KG BEFESTIGUNGSTECHNIK FASTENING TECHNOLOGY 36...

Page 122: ...PREBENA Wilfried Bornemann GmbH Co KG BEFESTIGUNGSTECHNIK FASTENING TECHNOLOGY 33 APPENDIX...

Page 127: ...PREBENA Wilfried Bornemann GmbH Co KG BEFESTIGUNGSTECHNIK FASTENING TECHNOLOGY 38...

Page 128: ...PREBENA Wilfried Bornemann GmbH Co KG BEFESTIGUNGSTECHNIK FASTENING TECHNOLOGY 39...

Page 214: ...PREBENA Wilfried Bornemann GmbH Co KG BEFESTIGUNGSTECHNIK FASTENING TECHNOLOGY 33 ANNEXE...

Page 219: ...PREBENA Wilfried Bornemann GmbH Co KG BEFESTIGUNGSTECHNIK FASTENING TECHNOLOGY 38...

Page 220: ...PREBENA Wilfried Bornemann GmbH Co KG BEFESTIGUNGSTECHNIK FASTENING TECHNOLOGY 39...