40

EGW05-SWHPEG-20140724

TM

TM

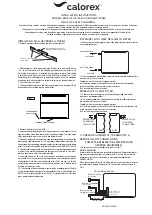

CONDENSATE DRAINS AND PIPING

The drain pans are connected to a common drain system. Connections are available on both sides of the base frame as

well as under the unit. The connection underneath the unit comes temporarily plugged from the factory. Field installation

of negative pressure condensate drain traps is required using one of these three connections. The non-trapped drain

connections must be permanently capped with a suitable PVC plug. See Figure 4-3 for more detail on the sizing and

materials of the negative pressure condensate drain trap.

For outdoor units, wrap drain lines and trap with electric heat tape (follow manufacturer’s instructions) controlled by an

automatic thermostat set at a minimum of 35°F to protect against freezing. Outdoor units also require insulation of all

external condensate piping. Insulation must be sealed at all seams.

NOTE

Power for heat tape must be supplied external to the PoolPak unit.

If the drain traps are vented to ambient pressure, they can be tied together after trapping and directed towards the nearest

roof or floor drain. Provisions

MUST

be made for disposal of condensate as directed by local plumbing code.

!

CAUTION

If condensate is returned to a closed filter system that does not have a surge tank,

care must be taken to ensure free flow of condensate back to the closed filter.

For additional questions or concerns regarding installation of condensate drains, please contact PoolPak™ Service.

Figure 4-3. Negative Pressure Condensate Piping Schematic

SWHP-NegPressCondPiping-20140408.eps

UNIT BASE

MINIMUM SCHEDULE 40 PVC

REMOVABLE

CLEANOUT

OPEN TEE

FOR VENT

NOTE: NOT TO SCALE

SWHP UNIT

PLUG THE

UNUSED

CONNECTION

WITH SUITABLE

PVC PLUG

1

2

4 INCHES MINIMUM OR MAX NEGATIVE STATIC

PRESSURE (INCHES W.C.) + 1 INCH

2 INCHES MINIMUM OR 1/2 x

1

1

2