7.12

ELECTRICAL

Coolant Fan Control Switch Operation Test

1.

Place switch in a liquid bath and submerse it to the base of

the threads. Do not allow threads to contact container or an

inaccurate reading will result.

2.

Heat the liquid slowly and monitor the temperature with a

thermometer or Fluke™ meter pyrometer. The switch

should be closed (conductive) at the “ON” temperature

indicated in the chart, and stay conductive until the “OFF”

temperature is reached.

Fan Motor Current Draw

A current draw test will provide a good indication of fan motor

condition. A worn or damaged fan motor will draw more

current, which causes a reduction in blade speed and reduced

cooling.

1.

Turn key off. Disconnect harness from fan switch on

radiator.

2.

Place a jumper wire between the Red / Blk and Org / Blk

wires in the fan switch connector.

3.

Disconnect the fan and place a jumper wire between the

brown wires in the connectors. This will provide a ground

path to the fan. Use caution as to not damage the wire

terminals.

4.

Place a DC ammeter in series as shown in the Illustration.

Verify fan blade is free to rotate.

5.

Turn ignition key and engine stop switch to “RUN”

position. Read the current draw on ammeter with fan

running.

6.

During start-up, the amperage should peak then decline

rapidly. If the motor continues to draw more amperage than

the fan circuit breaker rating during start-up, replace the

motor.

7.

If the fan motor draws more than 6.5 Amps during continual

running, check for debris blocking the fan, or replace the

motor.

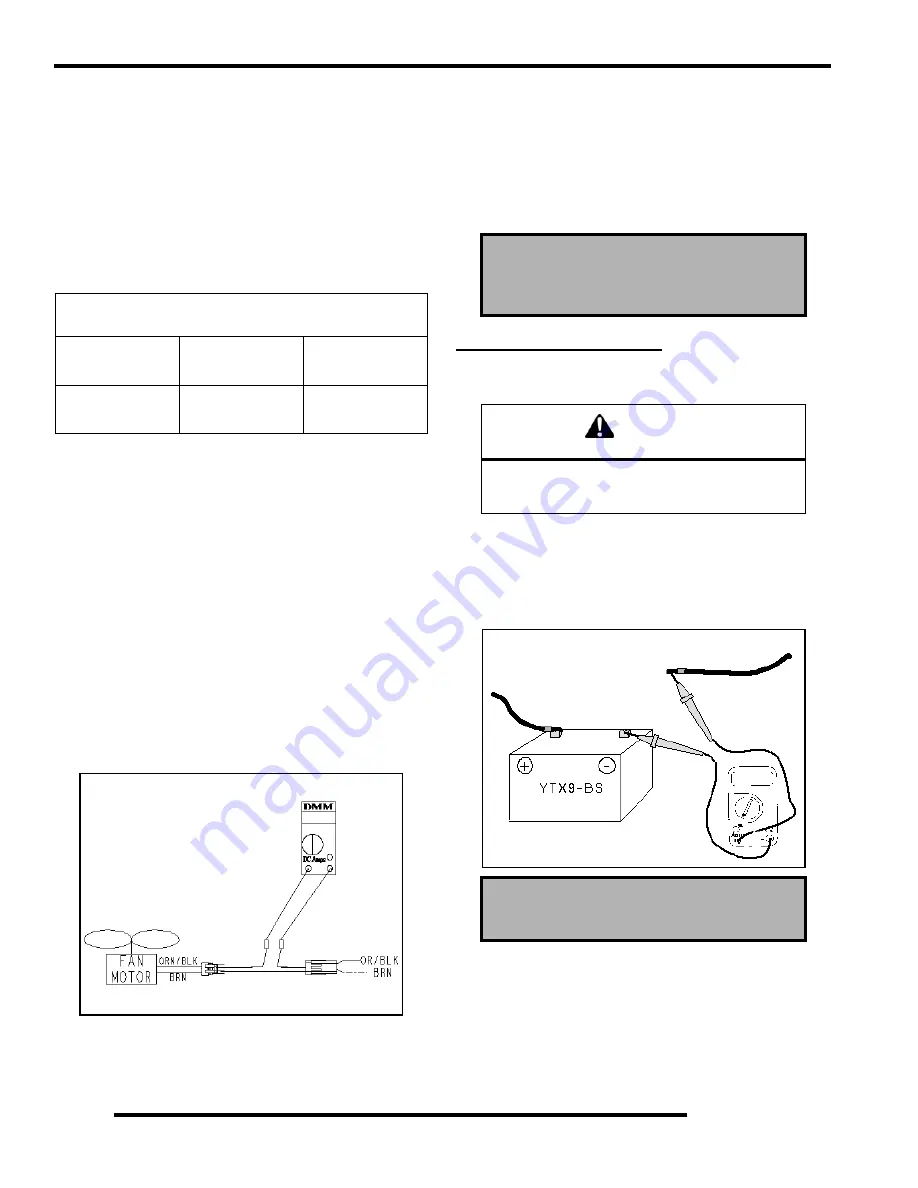

CHARGING SYSTEM

Current Draw – Key Off

Connect an ammeter in series with the negative battery cable.

Check for current draw with the key off. If the draw is excessive,

loads should be disconnected from the system one by one until

the draw is eliminated. Check component wiring as well as the

component for partial shorts to ground to eliminate the draw.

Refer To Parts Manual For Fan Switch Application

Fan Switch Type

Continuity

(On)

No Continuity

(Off)

Off / On

Thermistor

180

o

F (82

o

C) ±

3

o

F

150

o

F (65

o

C)

± 8

o

F

Connect ammeter leads to

each service tool terminal

Connect BRN Wires

Fan Motor Current Draw:

Less Than 6.5 Amps

CAUTION

Do not connect or disconnect the battery cable

or ammeter with the engine running.

Damage will occur to electrical components.

Current Draw - Key Off:

Maximum of .01 DCA (10mA)

Current Draw Inspection

Key Off

RepairPro Service Manual

Summary of Contents for Outlaw 500

Page 1: ...Fix it like a Pro...

Page 3: ......

Page 47: ...NOTES MAINTENANCE 2 32 RepairPro Service Manual...

Page 81: ...3 34 ENGINE Outlaw Cam Timing Exploded View RepairPro Service Manual...

Page 149: ...NOTES BODY STEERING SUSPENSION 5 40 RepairPro Service Manual...

Page 195: ...NOTES ELECTRICAL 7 22 RepairPro Service Manual...

Page 200: ...8 1 WIRE DIAGRAM OUTLAW 500...

Page 201: ...8 2 WIRE DIAGRAM OUTLAW 500 RepairPro Service Manual...

Page 202: ...8 3 WIRE DIAGRAM OUTLAW 500...