7-21. CLEANING, INSPECTION AND REPAIR OF MAIN GEAR OLEO.

a.

Clean all parts with a suitable dry type cleaning solvent.

b. Inspect the landing gear oleo assembly component for the following:

1. Bearings and bushings for excess wear, corrosion, scratches and overall damage.

2. Retaining pins for wear and damage.

3. Lock rings for cracks, burrs, etc.

4. Cylinder and orifice tube for corrosion, scratches, nicks and excess wear.

5. Orifice plate for hole restriction.

6. Fork tube for corrosion, scratches, nicks, dents and misalignment.

7. Air valve general condition.

c.

Repair of the oleo is limited to smoothing out minor scratches, nicks and dents and replacement of

parts.

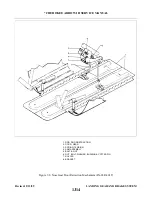

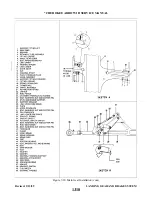

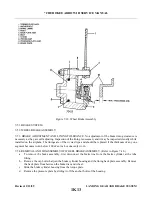

7-22. ASSEMBLY OF MAIN GEAR OLEO. (Refer to Figure 7-9.)

a.

Ascertain that all parts are cleaned and inspected.

5606) and install it on the plug. Lubricate the inside wall of the tube. Insert the plug into the top of the

tube (25) and push it to the fork end. Align the bolt holes of the fork, tube and plug, and install bolt

assembly.

c.

If desired, cement a cork in the hole in the bottom of the fork body to prevent dirt from entering

between the fork and tube.

tube and secure with snap ring (14).

e.

f.

Assemble the components of the piston tube (25) on the tube by placing, in order, the snap ring (24),

washer (23), lower bearing (20) with outer and inner O-rings (19 and 21) and upper bearing (18).

Align the two .125 diameter holes and the lock pin holes with the corresponding holes in the piston

tube (25) and install pins (17) without force. The outer surface of the pins must not protrude beyond

the outer diameter of the bearing (18).

g. Lubricate the wall of the cylinder oleo housing (11) and tube (25) and carefully insert the tube

h. At the top of the housing, tighten the locknut (6), torque nut 300 min. to 500 max. inch pounds.

i.

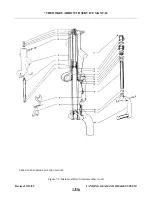

Ascertain that the bushings are installed in the upper and lower torque links (15 and 16) and then

install links. The torque link bolt assemblies (2, 3 and 4) should be lubricated and installed with the

flat of the bolt head hex adjacent to the milled stop of the wide end of the link. (Use the same thickness

of spacer washers between the two links as those removed to maintain correct wheel alignment.)

Tighten the bolts only tight enough to allow no side play in the links, yet be free enough to rotate.

j.

Connect the brake line and bleed the brakes per Paragraph 7-73.

k. Lubricate the gear assembly. (Refer to Lubrication Chart, Section II.)

l.

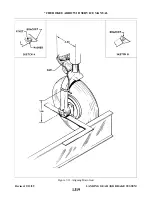

Compress and extend the strut several times to ascertain that the strut will operate freely. The weight

of the gear wheel and fork should allow the strut to extend.

m. Service the oleo strut with fluid and air. (Refer to Oleo Struts, Section II.)

n. Check main gear alignment (refer to Paragraph 7-27) and gear operation.

o. Remove the airplane from jacks.

Revised: 2/13/89

1J22

* CHEROKEE ARROW III SERVICE MANUAL

LANDING GEAR AND BRAKE SYSTEM

Summary of Contents for ARROW III

Page 4: ...THIS PAGE INTENTIONALLY LEFT BLANK 1A4...

Page 12: ...THIS PAGE INTENTIONALLY LEFT BLANK 1A12...

Page 94: ...Figure 4 2 Wing Installation Revised 2 13 89 1D22 CHEROKEE ARROW III SERVICE MANUAL STRUCTURES...

Page 171: ...lH3 INTENTIONALLY LEFT BLANK...

Page 172: ...lH4 INTENTIONALLY LEFT BLANK...

Page 286: ...THIS PAGE INTENTIONALLY LEFT BLANK Revised 2 13 89 2A8...

Page 528: ...INTENTIONALLY LEFT BLANK 2K10 THRU 2L24 2K10...