9

CX-692

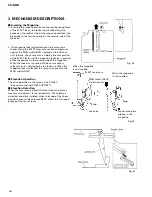

Lens kick mode jumping

The lens kick mode jumping is being executed by the

lens kick command being issued by the

microcomputer(IC501:PD5511A).The jumping direction

and the number of jumping tracks (1 - 255) are being

designated by the command. Receiving the lens kick

command, the LSI applies the kick pulse to the front

stage of the tracking EQ to execute the jumping. At

this time, the LSI works to control the moving speed of

the lens referring to the table carrying inside the LSI.

By this function, when the number of remaining tracks

is still large, the speed is raised, while the speed is

lowered as the number of remaining tracks decreases

to facilitate taking-in action by the servo when the jump

has been finished. While jumping is in progress, the

track counting is being made in observation of the RFRP

signals. Also, the jumping direction is being detected

by the phases of the RFRP and the TEZ1.

Meanwhile, when a track jumping has been finished, in

order to stabilize the taking-in action by the servo, the

tracking servo gain will be raised for about 2 to 3mS

after a jump has been finished, or with some jumps,

hysteresis movements are being employed.

8 track jumping

Equalizer

Hysteresis

TE

RFZC

(IC401's internal signals

being formed by the RFRP)

TEZC

(IC401's internal signals

being formed by the TEI)

GAIN UP

NORMAL

ON

OFF

2-3mS

The hysteresis ON for 2mS to 3mS

for 100 or 255 track jumping only

Fig. 10