User Manual

E727T0005, valid for E-727

BRO, 2019-06-28

Physik Instrumente (PI) GmbH & Co. KG, Auf der Roemerstrasse 1, 76228 Karlsruhe, Germany

Page 71 / 240

Phone +49 721 4846-0, Fax +49 721 4846-1019, Email

Example—"Position Distance" Trigger Mode

The "Position Distance" trigger mode is designed for scanning applications. A trigger pulse is

written whenever the axis has covered the distance set with CTO (<TriggerStep>). The unit of

<TriggerStep> is the physical unit of the axes (query with the PUN? command).

In addition to the basic configuration, the “Position Distance” trigger mode provides several

options:

Definition of pulse length, p. 72: variable (depending on velocity) or constant

Definition of thresholds for trigger limitation to a certain position range and

direction of motion, p. 74

Filter definition for reduction of false triggers, p. 76

Basic trigger configuration

The following parameters must be set for the digital output line which is to be used for trigger

output (<TrigOutID>):

Axis (<CTOPam> = 2)

TriggerMode (<CTOPam> = 3)

TriggerStep (<CTOPam> = 1)

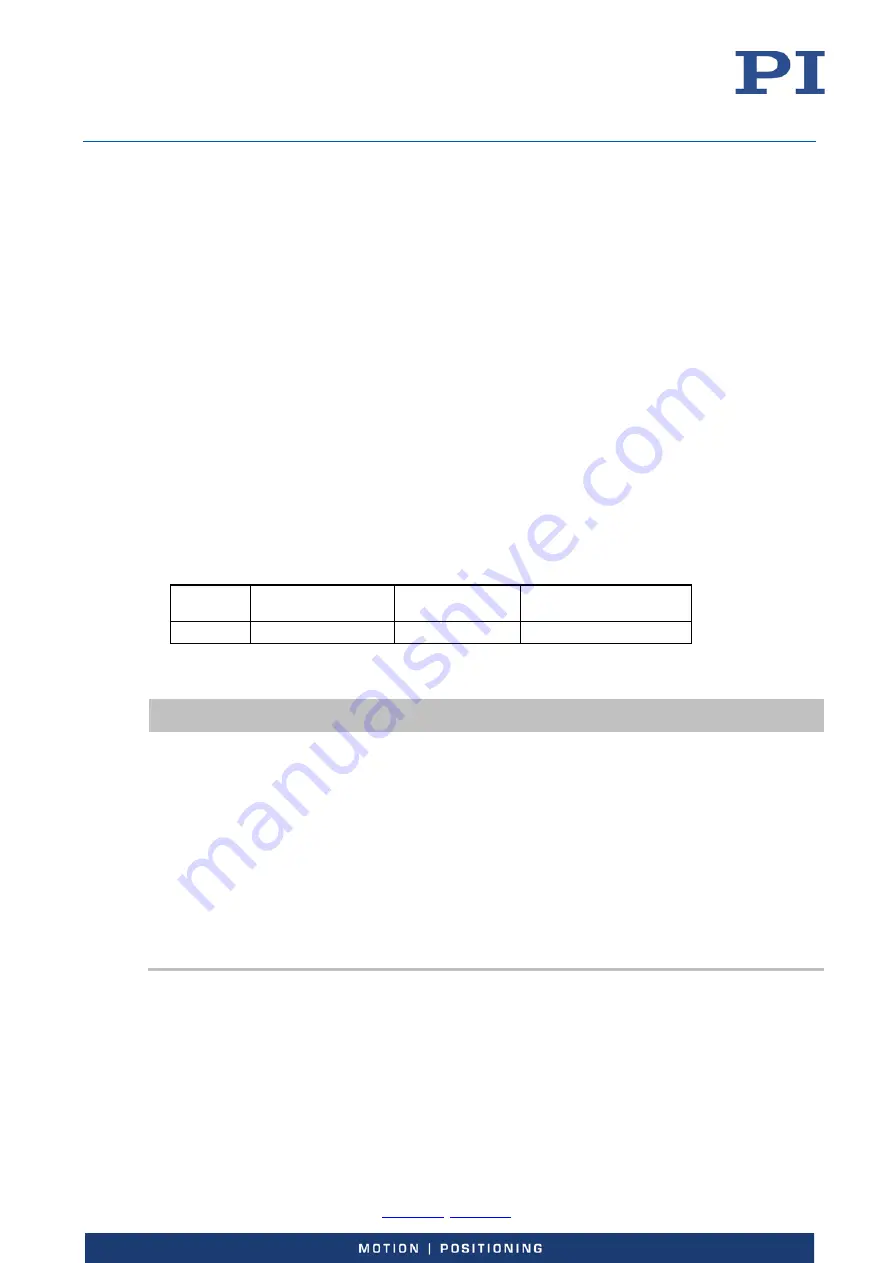

General notation of the CTO command for this mode (in fact, the command arguments can be

divided in three "portions", each starting with the <TrigOutID> declaration):

Command

mnemonic

Axis selection

Trigger mode

selection

Step size setting

CTO

<TrigOutID> 2

Axis

<TrigOutID> 3 0

<TrigOutID> 1

Stepsize

Instead of using the CTO command, you can also set the values of the corresponding parameters

with SPA or SEP, see “Configuring Trigger Output” (p. 69) for a parameter list.

INFORMATION

Possible values for TriggerStep depend on the axis velocity.

With high velocities, the minimum TriggerStep value is limited as follows:

TriggerStep > 4 * velocity * Servo Update Time

Servo Update Time is given in seconds by parameter 0x0E000200

Examples (the Servo Update Time of the E-727 is 50 µs):

o

With a velocity of 1000 µm/s, the minimum TriggerStep value is 200 nm.

o

With a TriggerStep value of 100 nm, the maximum velocity is 500 µm/s.

With very small velocities, the minimum TriggerStep value is limited by the noise of the

position sensor. For reliable triggering, the TriggerStep setting has to be at least 5 times larger

than the peak-to-peak level of the sensor noise. The sensor noise level can be reduced by

digital filtering of the signal (p. 27). To detect the noise, you can record, for example, the

position error of the axis using the data recorder.

Example: A pulse on the digital output line 1 is to be generated whenever axis 1 of the stage has

covered a distance of 0.1 µm. Send:

CTO 1 2 1 1 3 0 1 1 0.1