Configuration and startup

3827_en_B

PHOENIX CONTACT

–

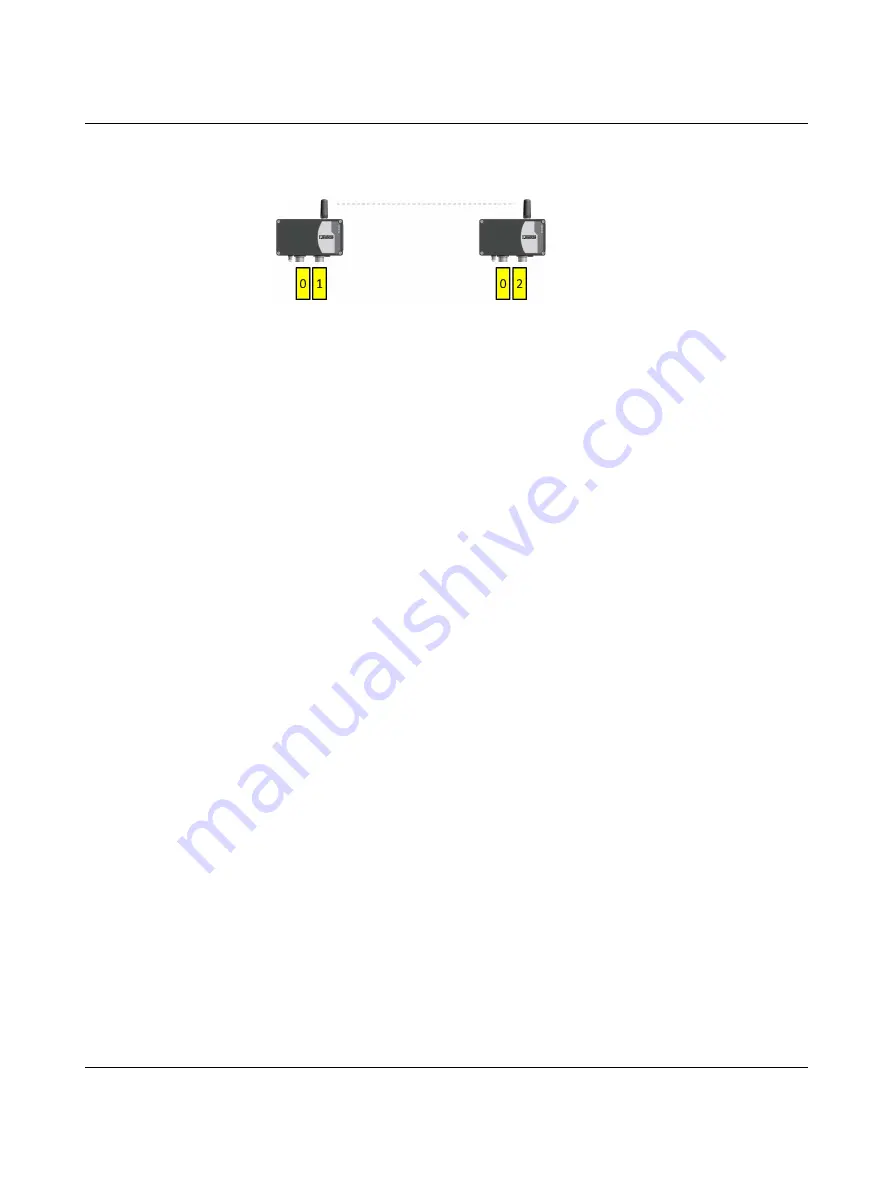

The RAD-900-DAIO6 may be used to create a point-to-point connection with another

RAD-900-DAIO6. In this case, one RAD-900-DAIO6 must have its address set to

01

and the other must be set to

02

.

Figure 5-15

Thumbwheel addressing of the RAD-900-DAIO6 in point-to-point mode

Wireless module in PLC/Modbus RTU mode

–

Multiple RAD-900-DAIO6 devices may not use the same thumbwheel address in a

single network.

–

The input and output data is saved in a Modbus memory map in the master wireless

module. You can read or write the process data via the serial interface of the master

wireless module (RAD ID = 01) using the Modbus RTU command. The process data

tables can be found starting at “Modbus memory map” on page 100.

5.8.2

RAD-900-DAIO6 in PLC/Modbus RTU dual mode

–

Each wireless module is assigned a Modbus address. The Modbus address of each

module is that of the RAD-ID (yellow thumbwheel) set on the module. The master

wireless module Modbus address may be changed from

01

, if an existing Modbus

device is already assigned this address. A Modbus address may only appear once in

the network.

–

Each RAD-900-DAIO6 device must use a unique thumbwheel address within a single

network.

–

The input and output data is saved in a Modbus memory map in the wireless module.

You can read or write the process data via the serial interface of the master wireless

module (RAD ID = 01) using the Modbus RTU command. The process data tables can