VARI

❋

LITE - VL3015LT S

POT

L

UMINAIRE

S

ERVICE

M

ANUAL

1 2 8

0 2 . 9 6 9 8 . 0 0 1 0 0

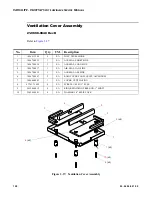

Ventilation Cover Assembly

21.9698.0840 Rev D

Refer to

Figure 3-37: Ventilation Cover Assembly

No.

Item

Qty.

UM.

Description

1

10.9661.1249

4

EA

POST, TRUSS HOOK

2

10.9678.0835

1

EA

AIR SEAL, SHORT SIDE

3

10.9678.0836

1

EA

AIR SEAL, LONG SIDE

4

10.9678.0837

1

EA

AIR SEAL, FAN SIDE

5

10.9678.0838

1

EA

AIR SEAL, APS SIDE

6

10.9678.0887

2

EA

RAIN COVER FOAM, QUIET, ALUMINUM

7

10.9686.0883

1

EA

COVER, VENTILATION

8

53.7017-1000

4

EA

SCREW, 1/4-20 X 1" SCSS

9

54.1206.0015

4

EA

RING, RETAINING, PRESS-ON, 1" SHAFT

10

55.6549.0001

4

EA

WASHER, 1/4" SPLIT LOCK

1

(x4)

7

8

(x4)

9

(x4)

10

(x4)

2

5

4

3

6

(x2)

Summary of Contents for Vari-lite VL3015LT

Page 1: ......

Page 13: ...FOREWORD 02 9698 0010 0 xi ...

Page 14: ...VARI LITE VL3015LT SPOT LUMINAIRE SERVICE MANUAL xii 02 9698 0010 0 ...

Page 78: ...VARI LITE VL3015LT SPOT LUMINAIRES SERVICE MANUAL 60 02 9698 0010 0 Notes ...

Page 112: ...VARI LITE VL3015LT SPOT LUMINAIRE SERVICE MANUAL 94 02 9698 0010 0 Notes ...

Page 130: ...VARI LITE VL3015LT SPOT LUMINAIRE SERVICE MANUAL 112 02 9698 0010 0 Notes ...

Page 136: ...VARI LITE VL3015LT SPOT LUMINAIRE SERVICE MANUAL 118 02 9698 0010 0 Notes ...

Page 182: ...VARI LITE VL3500 SPOT LUMINAIRE SERVICE MANUAL 164 02 9698 0010 0 Notes ...

Page 183: ......