17” CDT Color Monitor 107S7

81

Per Philips make-up sheet

5.5 Color for resin/paint

Per Philips make-up sheet

5.6 Resins

•

RoHS requirements.

•

WEEE requirements.

5.7 If paint is used

•

RoHS requirements.

•

WEEE requirements.

5.8 Plastic mold tooling

•

Tooling to be designed to minimize cosmetic defects induced by molding process (sink, blush, weld lines, gate

marks, ejector marks, etc.).

•

Painting to cover up cosmetic defects due to molding is strongly discouraged.

5.9 Plastics flammability

•

All Plastics expect Base / Pedestal to be Flame Retardant UL 94-V0 or Better (if monitor weighs less than 18kg;

UL94-V0 is OK).

•

Base / Pedestal to be Flame Retardant UL 94-HB (ABS).

•

All major plastic parts (bezel, back cover) need to be molded from same resin. Base / Pedestal otherwise

specified.

5.10 Texture/Glossing of housing

•

The texture area and texture no. should follow Philips make-up sheet.

•

The exterior surfaces shall have a uniform texture.

•

Philips must approve the mold texturing.

•

Detail document for texture refer to UAN-D249.

•

< = 20 gloss units

5.11 Tilt/Swivel Base ranges

•

Tilt Range -

Up = 14°

±

1°, Down = 3.5°

±

1°

•

Swivel Range -

± 90°

Summary of Contents for 107S7

Page 12: ...17 CDT Color Monitor 107S7 12 ...

Page 18: ...17 CDT Color Monitor 107S7 18 Fig 4 Fig 5 Fig 6 ...

Page 33: ...17 CDT Color Monitor 107S7 33 8 Mechanical of cabinet front dis assembly ...

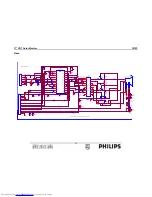

Page 62: ...17 CDT Color Monitor 107S7 62 13 PCB Layout 13 1 Main PCB layout ...

Page 63: ...17 CDT Color Monitor 107S7 63 13 2 CRPC Board layout ...