Malfunctions

33

9

Malfunctions

9.1

General

Turbopump and electronic drive unit malfunctions always result in a warning or error

message. In both cases, the electronic drive unit outputs an error code. Operating mes-

sages are generally displayed via the LEDs on the electronic drive unit. If an error occurs,

the turbopump and connected devices will be switched off. The selected venting mode

will be triggered after the preset delay.

9.2

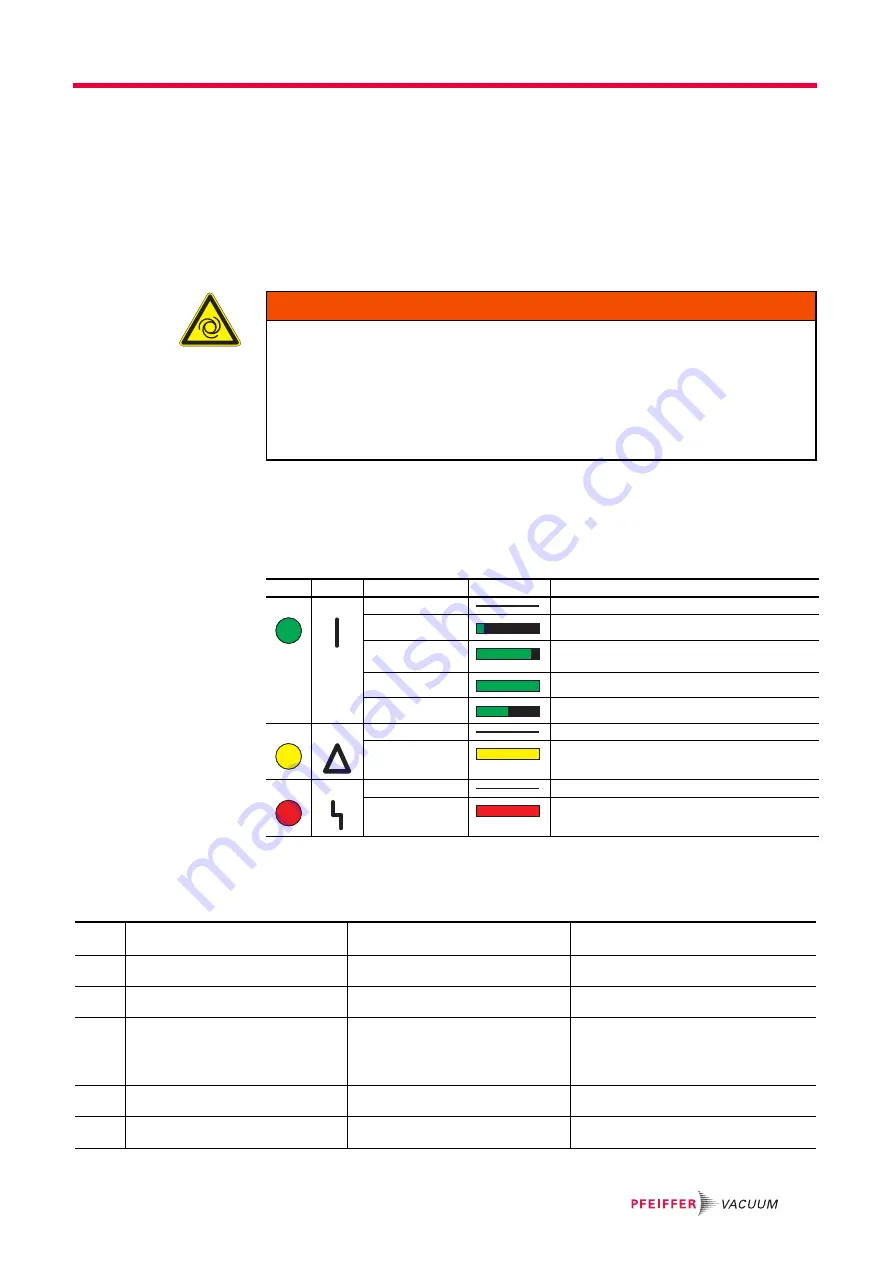

Operation display via LED

LEDs in the front panel of the electronic drive unit show basic operating conditions of the

turbopump. A differentiated malfunction and warning display is possible only for opera-

tion with DCU or HPU.

Fig. 8:

Behaviour and meaning of LEDs on the electronic drive unit

9.3

Error codes

WARNING

Automatic start-up after power failure or malfunction acknowledgement

The function "pumping station" of the electronic drive unit remains active after power

failure or errors that lead to shut down the pump or the system. The turbopump runs up

automatically after power ist restored or malfunction acknowledgement.

Switch off the function "pumping station" if necessary.

Provide safety measures against interference in the high vacuum flange while the tur-

bopump is running.

LED

Symbol LED status

Display

Meaning

Green

Off

currentless

On, flashing

"Pumping Station OFF", rotation speed

≤

60 min

-1

On, invers flashing

"Pumping Station ON", set rotation speed not at-

tained

On, constantly

"Pumping Station ON", set rotation speed attained

On, blinking

"Pumping Station OFF", rotation speed > 60 min

-1

Yellow

Off

no warning

On, constantly

Warning

Red

Off

no malfunction

On, constantly

Malfunction

Error

code

Problem

Possible causes

Remedy

Err001

Overspeed

Call Pfeiffer Vacuum Service

Only acknowledge for rotational speed f = 0

Err002

Overvoltage

– Incorrect power pack used

Check power pack type

Check partial mains voltage

Err006

Run-up fault

– Run-up time threshold set too low

– Gas flow in recipient through leaks or

open valves

– Speed-control switching point not

reached upon expiration of run-up time

Adjust run-up time to process conditions

Check recipient for leakage and closed

valves

Adjust speed-control switching point

Err007

Insufficient operating materials

– Insufficient operating materials

Check operating materials

Only acknowledge for rotational speed f = 0

Err008

Connection from electronic drive unit to

pump faulty

– Connection to pump faulty

Check connections

Only acknowledge for rotational speed f = 0