6. Lightly rub the surface with emery cloth (grain size 180).

– Never oil the guide pins, this has an adverse effect on damping.

– If necessary, replace completely if there are pronounced traces of wear.

7. Clean the other parts.

8. Inspect all parts for wear and replace if necessary.

Install the overflow valve

1. Mount the ball, compression piece, and spring.

2. Lock the thread on the pressure screw with

Loctite 243

.

3. Screw in the pressure screw.

4. Locate the valve plate in the overflow channel.

5. Install the O-ring in the appropriate groove.

6. Place the valve cover on the housing.

7. Tighten the screws crosswise.

– Tightening torque:

25 Nm

7.7 Installing coupling

WARNING

Danger of injury due to exposed rotating parts

In the operating range of the motor coupling, there is a danger of clothing being caught and wound

up.

► When assembling the motor and coupling, make sure that the coupling protection is seated cor-

rectly.

► Wear correct clothing.

Coupling assembly

Observe the installation instructions of the coupling manufacturer.

Required tools

● Allen key, WAF 2.5 mm

● Allen key, WAF 6 mm

● Calibrated torque wrench (tightening factor ≤ 2.5)

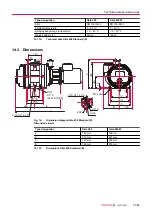

3

2

5

4

6

7

8

E

1

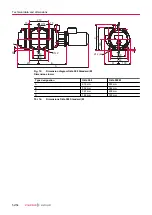

Fig. 13:

Installation instructions gear rim coupling

1 Stud screw (T

A

)

5

Lock washer

2 Coupling half motor

6

Washer

3 Toothed ring coupling hub

7

Coupling half pump side

4 Cylinder screw (T

P

)

8

Clearance E

Procedure

1. Precisely adhere to the prescribed installation dimensions.

– Angular and radial displacement of the shafts.

– Clearance E:

18 mm

.

2. Lock the thread on the stud screw with

Loctite 243

.

3. Tighten the stud screw in the motor side coupling half.

– Tightening torque T

A

:

2 Nm

4. Install the pump side coupling half.

Maintenance

38/54