Assembly & Operation Manual

10. Install the turnstile housing on anchor sleeves and fix it with M10 bolts using S17

socket wrench. Check the position of the housing with the level.

11. If it is necessary to set up the turnstile into potential control mode remove the

jumper on the

J1

connector of the CLB.

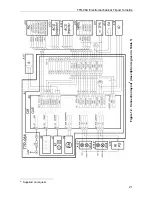

12. Connect the RC panel cable (14) (WRC / ACS controller) to

XS1

connector block.

13. Connect the additional equipment if necessary (intrusion detector and a siren;

emergency unblocking device (

Fire Alarm)

; remote indicators).

14. Connect the power cable

(11) from the turnstile power supply

to

XS1

connector

block.

15. If needed, install the proximity card readers into the special places, situated in the

housing (5 in Fig. 11). To connect card readers use free contacts (15 - 24) of the

XS1

connector block.

Caution!

In order to install readers, manufactured by other companies, please note that they

are to comply with the following characteristics:

dimensions (length × width × height) ..................................... max 145×90×25 mm

card reading distance ........................................................................... min 70 mm

In case of use of card readers with read range fewer than 7cm, the steady reading

of cards during their validation is not guaranteed

5

.

16. Check serviceability and accuracy of all the electrical connections. Fasten all the

cables in two points to the hole in the turnstile housing horizontal plane, using hook

and loop cable ties.

17. Install the back panel in reversed order.

18. Install the reinforcement plate on the turnstile in reversed order.

19. Connect the indication board cable header to the

S1

connection slot.

20. Mount the cover with LED indication back into its place in the reverse order. When

the cover with LED indication mounting is carried out correctly it does not need

much effort. Fasten the cover with the bolts.

21. Install the hub (5) with the barrier arms (3) in the following order:

Insert the hub into a corresponding mounting face on the turnstile mechanism shaft.

Caution

!

For proper hub installation before the final tightening of the bolts, barrier arm is to be

shifted into a horizontal position and a 90º degree angle in the horizontal between

the barrier arm and the turnstile housing is to be set with a set square.

Fix the hub with hub fastening bolts (6), inserting a split washer under each bolt

head. Bolts’ tightening is to provide solid hub fixation regarding the turnstile

mechanism shaft (without gaps and mismatches).

22. Install the plugs (16).

Run a test switch on of the turnstile as specified in clause 9.1

«Power-up»

.

5

PERCo produces IP-based entrance control systems KT-08.3A with similar design which has got

built-in ACS controller and built-in card-readers. Their read range is at least 6 cm from the

turnstile's cover.

20

Summary of Contents for TTR-08A

Page 34: ...www perco com...