thoroughly.

Slots

Some of the parts of our kits are designed to

fit, perpendicularly, either into or through slots

i n other parts. The slots are intended to

provide a loose sliding fit for the other part.

Because of variations in the degree of etching

(q.v., below)

, it is possible that the fit will be

looser or tighter than ideal.

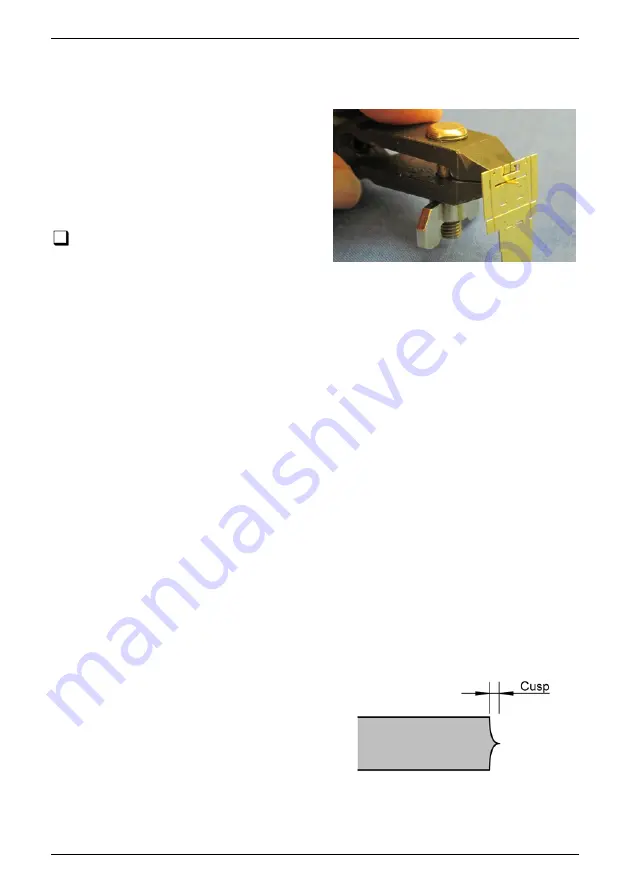

Check the width of each slot with a piece

of scrap etch before assembly, preferably

before folding the slotted part. If the scrap will

not pass through, hold it in pliers or a hand vice, as shown (though make sure the part is

well supported), and work it through the slot until the loose sliding fit is achieved. In tight

spots, it is possible to use a small drill held in a pin chuck as a file.

Degree of Etching

The etch is created for us by a third party industrial manufacturer using a process of

chemical erosion. The 'Degree of Etching', i.e. how long the metal sheet is left in the

chemical bath, is a variable which is set by the skill and judgement of the operator as

each batch of sheets is produced. That dictates that the sizes of the etched parts on

different sheets can vary, within a certain tolerance, around the nominally designed

values. The variation is more significant with the relatively thick materials, that we use in

the main structural parts of our kits, than it is with the thinner materials typically used for

detail parts.

The ideal degree of etching is indicated by the slots (see above), as manufactured, being

just slightly on the tight side of the easy sliding fit required. The range of degree of

et c hing which we deem to be acceptable is from a 'lighter' etch, in which the scrap

material has to be pushed through the slot quite firmly to achieve the clearance, to a

'heavier' etch, where the fit is a little loose. We have test built our kits from etches

across this range to confirm that they may be assembled successfully.

Cusps

The chemical erosion process works equally

from each side of the metal, resulting in the

edges of the etch having shaped 'cusps' as in

the diagram here. On edges which will be

visible on the finished model, it is good practice

to file the edges of the metal flat. Many of the

edges on our kits are hidden from view.

Where

edges

form

joints

with

other

components, on a 'lighter' etch the edges may

need to be filed to a flat surface to achieve a fit, whereas with a 'heavier' etch one might

leave more of the cusps in place. In places which can't be reached by a file, e.g. in acute

corners of the etch, the cusp may be pared away with a sharp knife.

General Notes

6/51

(c) PenBits Model Railways, All Rights Reserved

27/09/2021

Summary of Contents for BACHMANN CLASS 24

Page 2: ......