Microdrive Series Instruction Manual

4201-109 Rev I

107

APPENDIX 6: TORQUE CONTROL USING THE MICRODRIVE CURRENT LIMIT

the drive if the Microdrive operates in current limit for a

prescribed time. This feature may be useful when the torque limit

is being used for mechanical protection.

In general:

When being used as a torque limiting controller (e.g.,

winder control), current limit mode (Screen 75) should

be set to TQ (torque).

When being used for current limiting, current limit mode

(Screen 75) should be set to I (current).

When attempting to provide very light torque control

(e.g., below 30%) reducing the motor rated voltage

(Screen 11) will improve the sensitivity of control by

increasing the motor current for a given level of torque.

The motor may not then, however, be able to provide full

rated torque should this be required. Alternatively, use

of dynaflux (Screen 25) will make the torque control

become non-linear allowing fine low torque adjustment,

but still provide the possibility of achieving full rated

torque.

When attempting to control a process torque (e.g., web

tension) always ensure that the process torque is much

larger than loss torques (such as the inefficiencies of

gearboxes and drivetrains). Difficulty in control occurs

when a small process torque is to be controlled, but is

dominated by fixed or variable system losses.

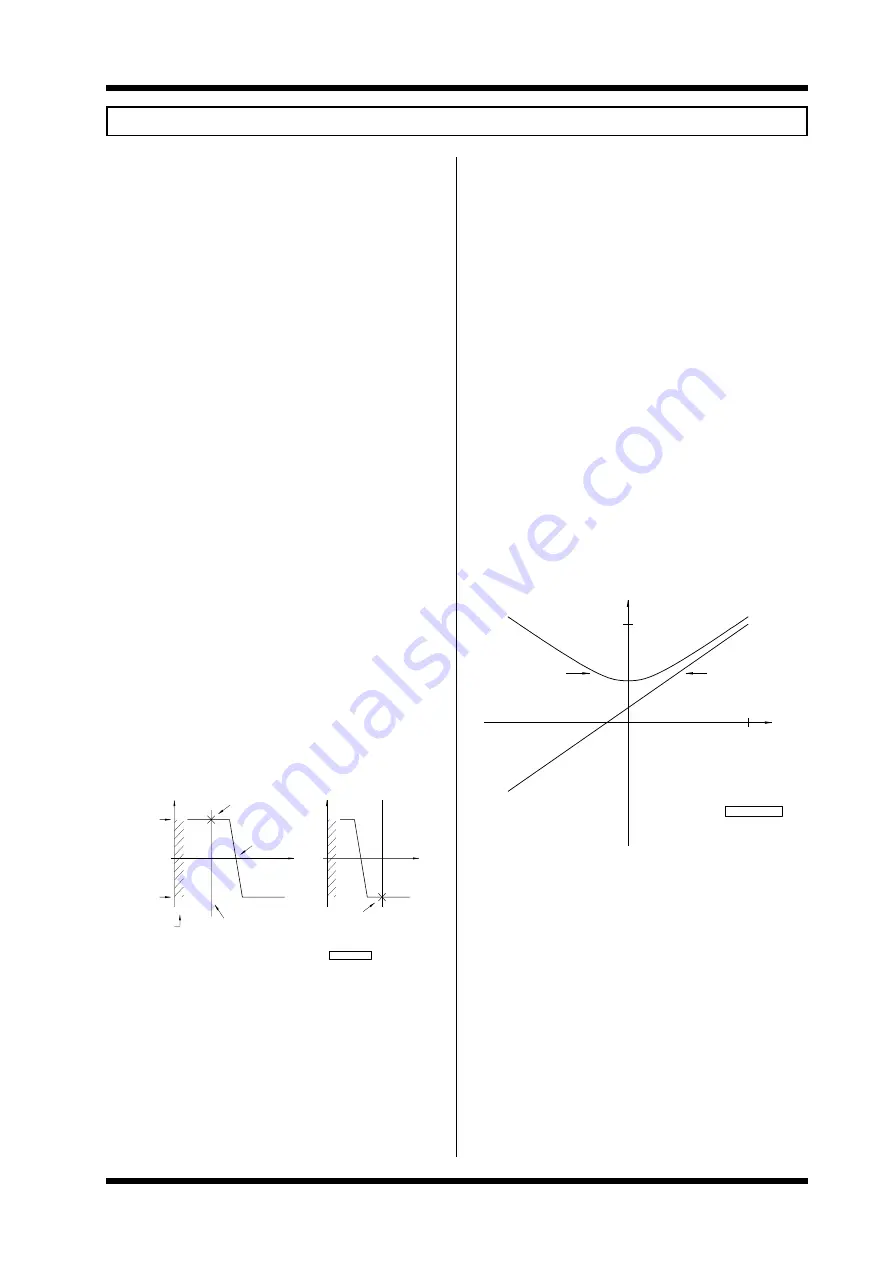

CURRENT

INVERTER CURRENT

100%

4807−176 Rev B

TORQUE CURRENT

TORQUE

100%

6A:

GENERAL NOTES

The Microdrive current limit can be configured as an adjustable

torque limit for many torque sensitive or torque controlled

processes.

The specific load control configuration is programmed via

adjustment Screens 18, 19 and 20 and by mode Screens 75 and

76.

The Microdrive will always operate as a speed controller but the

speed control will be over-ridden when the limiting condition is

encountered (see fig. below). The current limit will operate with

both braking and motoring torques.

If the inverter speed reference is set above that of the process

speed, the inverter will limit in the motoring mode and if the

reference is less than the process then the limit will be in the

braking mode (some means, e.g., a dynamic brake, must be

provided to dissipate the regenerated energy under braking

mode).

The current limit level can be preset to the I LIMIT parameter

(Screen 18) or adjusted via the 420mA or 010V analogue

inputs according to the sources selection (Screen 76), which

provide means of external control.

Torque is only proportional to current when the motor runs with

constant magnetic flux. This means the following conditions

must be met to achieve linear torque control:

-

minimum flux (Screen 25) must be set to 100%.

-

the inverter must be operating in the constant torque

region of operation (i.e., output volts less than or

equal to supply volts).

-

the output frequency must be greater than 3 times

slip frequency.

-

the current limit mode (Screen 75) should be set to

torque.

PROCESS LOAD LINE

(FIXED SPEED)

OPERATING POINT

(MOTORING)

REFERENCE SPEED

+ LIMIT

(ADJUSTABLE)

(ADJUSTABLE)

− LIMIT

TORQUE CONTROL

NOT AVAILABLE

IN THIS REGION

TORQUE

4807−175 Rev B

SPEED

(GENERATING)

OPERATING POINT

TORQUE

SPEED

For best results autoboost (Screen 77) should be selected to

ensure the correct flux is achieved at reduced speeds.

The stability and response of the torque loop is determined by

the ILT SLIP parameter (Screen 20). This is typically set to the

percentage slip of the motor. Reducing this value improves

stability but degrades response time, especially at low

frequencies. If the acceleration and deceleration times are set

too low the response times will also be degraded.

The current limit timeout parameter (Screen 19) can be set to trip

Summary of Contents for D3-2.5

Page 2: ...Microdrive Series Instruction Manual 4201 109 Rev I 4201 003 Rev A Page 2 of 12...

Page 6: ...Microdrive Series Instruction Manual 4201 109 Rev I 4201 003 Rev A Page 6 of 12...

Page 12: ...Microdrive Series Instruction Manual 4201 109 Rev I 4201 003 Rev A Page 12 of 12...

Page 55: ...Microdrive Series Instruction Manual 4201 109 Rev I 55...

Page 74: ...Microdrive Series Instruction Manual 4201 109 Rev I 74...

Page 75: ...Microdrive Series Instruction Manual 4201 109 Rev I 75...

Page 76: ...Microdrive Series Instruction Manual 4201 109 Rev I 76...

Page 77: ...Microdrive Series Instruction Manual 4201 109 Rev I 77...

Page 78: ...Microdrive Series Instruction Manual 4201 109 Rev I 78...

Page 79: ...Microdrive Series Instruction Manual 4201 109 Rev I 79...

Page 80: ...Microdrive Series Instruction Manual 4201 109 Rev I 80...

Page 81: ...Microdrive Series Instruction Manual 4201 109 Rev I 81...

Page 82: ...Microdrive Series Instruction Manual 4201 109 Rev I 82...

Page 83: ...Microdrive Series Instruction Manual 4201 109 Rev I 83...

Page 112: ...Microdrive Series Instruction Manual 4201 109 Rev I 112...

Page 113: ...Microdrive Series Instruction Manual 4201 109 Rev I 113...