MANUAL: 55308

REV: A

ECO: 49582

9

When subjected to elevated temperature, all

piezoelectric sensors/hardline cable systems exhibit

decreased insulation resistance, due in part to the

piezoelectric element, but due mostly to the hardline

cable necessary to withstand the high temperatures.

This situation can cause serious voltage offset

problems in direct-coupled charge amplifiers. To

solve this problem, the user must AC couple

(capacitor) the charge amplifier to the sensor/cable

system. See 5.3 Solution to Reduced Resistance , for

complete details, or use different amplifiers.

5.2 Reduced Resistance at

Charge Amplifier Input

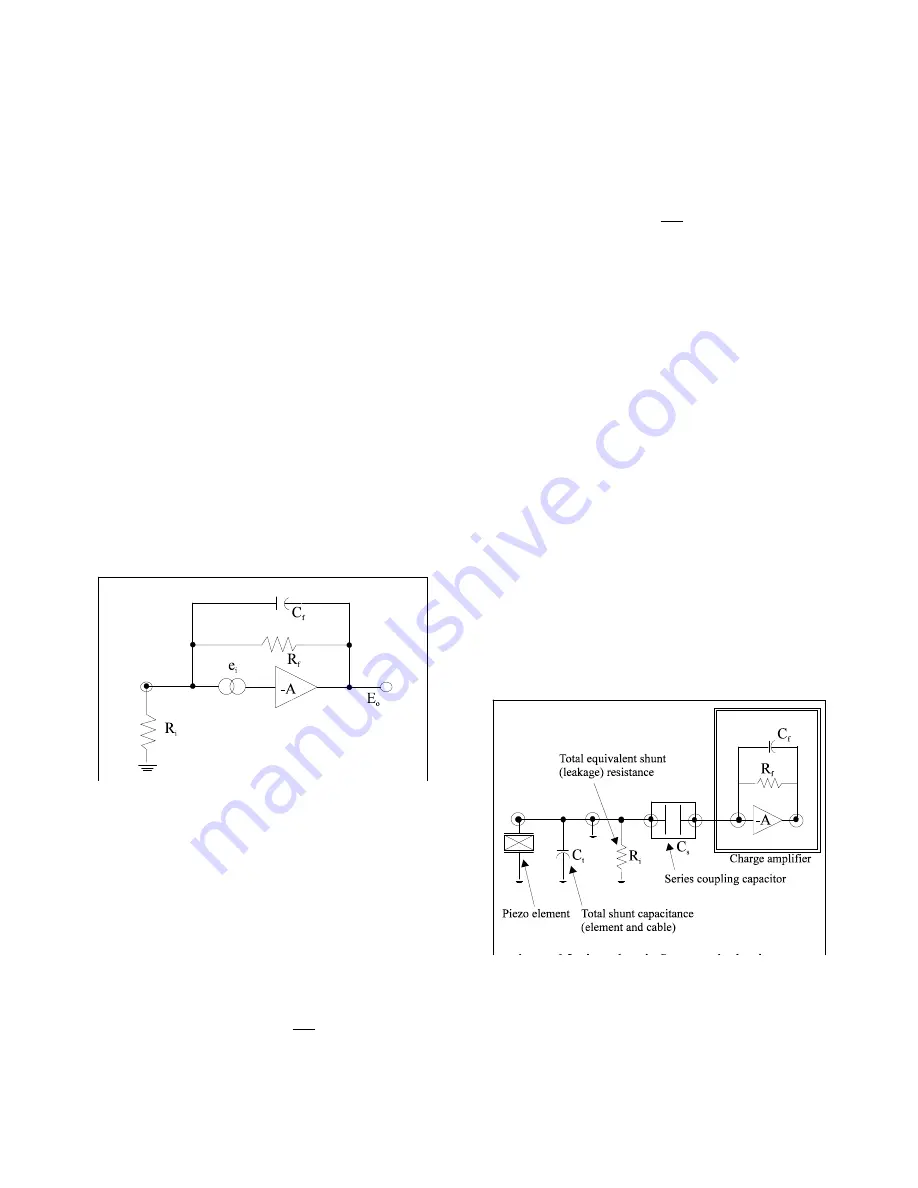

Figure 5.1 illustrates a simplified schematic of a

typical direct-coupled charge amplifier where:

R

f

= Feedback resistor (ohms)

R

i

= Input leakage resistance (ohms)

E

o

= Steady-state output voltage

(volts)

e

i

= Offset voltage: FET leakage

(volts)

C

f

= Feedback capacitor (farads)

Figure 5.1 Typical Charge Amplifier Schematic

The feedback capacitor C

f

comes into play only in

the dynamic situation and its influence does not

affect the steady-state situation. The voltage e

i

is a

DC offset voltage, usually very tiny (microvolts), that

exists at the input gate of the MOSFET circuit. This

minute leakage current exists in all real devices.

As demonstrated in Equation 1, the steady-state

(DC) output voltage E

o

is:

Equation 1

i

f

i

o

R

R

e

E

1

This equation shows that if the input (leakage)

resistance at the charge amplifier is extremely high

(approaching infinity), the output DC voltage

approaches e

i

, usually a very tiny voltage.

However, as R

i

decreases, the term

i

f

R

R

1

increases, such that the output voltage can, with

large ratios of R

f

/ R

i

, become large enough to result

in a large E

o

, perhaps large enough to be outside

the normal output voltage range of the charge

amplifier.

Because of the feedback capacitor C

f

, this output

voltage change usually does not occur rapidly but

rather, it manifests itself as a slow drift in the output

voltage level. If R

i

is low enough with respect to R

f

,

the voltage drift may continue until saturation of the

charge amplifier occurs.

5.3 Solution to Reduced

Resistance

Since the drift or offset problem is caused by a static

or steady-state imbalance at the input of the charge

amplifier, the solution involves blocking this steady-

state effect while allowing the desired dynamic

phenomena to pass. This may be accomplished by

installing a series capacitor at the input of the

charge amplifier, between the offending sensor (or

low-impedance hardline) and the input.

Figure 5.2 Piezoelectric System Block Diagram

Figure 5.2 illustrates a block diagram of the piezo-

electric system where:

C

t

= Shunt capacitor

C

s

= Series blocking capacitor